Europe and Japan celebrate achievement of important JT-60SA milestones

The concurrent achievement of several important milestones of the JT-60SA project was celebrated by some 200 high-level European and Japanese guests at the JT-60SA project site in Naka, Japan, on 20 April. The JT-60SA project is a “satellite” to the international ITER project and aims to model proposals for optimising plasma operation and investigate advanced plasma modes that could be tested on ITER or used later on DEMO. This satellite tokamak programme was established in 1997 as one of three joint projects between Europe and Japan within the Broader Approach Agreement.

Hosted by the Japanese Atomic Energy Agency (JAEA), the Japanese Implementing Agency for Broader Approach activities, the event was in celebration of the excellent progress achieved to date, with the coincidence of four major achievements. Interest in the project was clearly high – the celebration and the reasons behind it were also covered in several print, online and audio-visual media reports.

Yutaka Kamada, the Japanese home team project manager and Pietro Barabaschi, the European home team project manager and acting Director of Fusion for Energy, welcomed the guests and acted as masters of ceremony. Addresses by high ranking representatives of the Japanese government, European Embassies and the European Commission expressed satisfaction with the contributions of all institutions involved, and drew attention to the mutual trust that had developed between the partners. Finally the Project Leader of JT-60SA, Hiroshi Shirai, gave an overview of the state of the project. After a tree planting ceremony, guided tours of the site offered visitors the opportunity to see for themselves the state of technical achievements in the different areas.

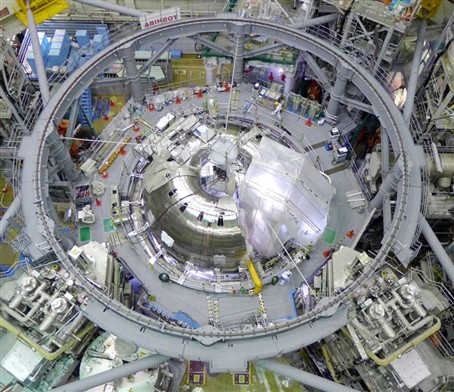

The first achievement concerned the assembly of 17 out of 18 sectors of the plasma vessel (the double-walled vacuum vessel which will enclose the 100 million degrees hot plasma). This large vessel 6.6 m high and 10 m in diameter was manufactured by Toshiba as part of JAEA´s contribution to the JT-60SA project. All stringent pressure and leak tests have been passed successfully and all tight manufacturing tolerances have been maintained.

The second achievement was the completion of the installation and testing of the quench protection system for the superconducting coils, which create a magnetic bottle to confine the plasma for the fusion reaction. If, for whatever reason, part of the coils stop being superconducting, the quench protection system avoids overheating of the coils by immediately discharging their stored electromagnetic energy into a set of resistors. The system is composed of 13 units applying the most advanced hybrid mechanical-static circuit breaker technology to interrupt currents of more than 25 kA at voltages of about 5 kV. It was procured by Italian CNR acting through Consorzio RFX in Padua. The contractor was Nidec ASI company. The system has just been installed and commissioned at JAEA, and the acceptance tests are being completed in April according to the agreed schedule before ownership is transferred to JAEA.

The third achievement was the arrival of the main subsystems of the cryogenic system on site. The cryogenic system is a very powerful fridge able to reach temperatures close to absolute zero (-269 degrees C). This system is provided by the French CEA Grenoble through their contractor Air Liquide Advanced Technologies. The main duty of the cryogenic system is to maintain the magnetic coils in a superconducting state. At the end of March all subsystems of the cryogenic system arrived in Japan and are now being assembled and commissioned. Just beforehand, again on schedule, JAEA finished construction of a new compressor building and the refurbishment of an existing hall for the refrigerator coldboxes.

The electrical connection between the warm power cables of the magnet power supply and the cold superconducting electrical network of the coils is realised by special helium-cooled connectors, so-called current leads. Twenty-six such current leads are being developed, manufactured and tested in a dedicated test facility by Karlsruhe Institute of Technology (KIT) in Germany. The current leads use high-temperature superconductor (HTS) tapes to reduce the resistive losses while creating a thermal barrier to reduce the heat flow to the very cold electrical networks. After their successful test at nominal operation conditions, KIT delivered the first two HTS current leads very recently to JAEA – the fourth achievement. The remaining current leads are in different advanced stages of construction and testing and will be delivered subsequently.