JT-60SA’s TF coil superconducting for the first time

A major milestone for the JT-60SA project, the machine’s first Toroidal Field (TF) coil has completed its cryogenic temperature 4.5k tests at the Cold Test Facility at CEA Saclay. “The coil became superconductive and reached its design full current (25.7kA) without any problem”, enthuses Pietro Barabaschi, Home Team Project Manager for Europe’s contribution to the Broader Approach (BA) project. Following hydraulic tests where the helium flow of the TF coil, manufactured by General Electric (formerly Alstom), proved to be fully in line with expectations, the coil also underwent the so-called quench test. Superconducting coils are needed to confine the fusion plasma, but if, for whatever reason, the coils stop being superconducting, it is necessary to immediately discharge them to avoid damage from overheating. The quench test checks that the coil will perform in line with its design specifications and involves raising the temperature of the TF coil while loaded with its full current, until it eventually loses superconductivity, becomes resistive and discharged in a fully controlled way. The quench was successfully achieved with a Helium inlet temperature of ~7.5 Kelvin, above the expected current sharing temperature of ~7.3K, in order to simulate what the TF coil will have to undergo once assembled and in operation.

Next steps now entail assembling this TF coil with some additional structural elements and shipping it to Japan for final tokamak assembly this summer. Two additional coils (one from ASG, the other from General Electric) will arrive for testing at CEA Saclay in the coming weeks. The testing of all coils is expected to be achieved by the summer of 2017.

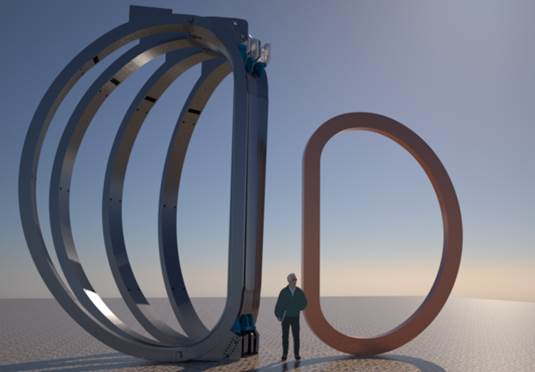

JT-60SA will employ a total of 18 TF coils. Including two spares, a total of 20 coils will be delivered to the JT-60SA site in Naka, Japan. Half of the coils are currently being manufactured at the General Electric factory in Belfort (France) and half at theASG factory in Genoa (Italy). The European institutes responsible for these contracts are CEA and ENEA respectively.

F4E procured the superconducting strands manufactured by the Furukawa Company in Japan (completed in May 2013) and their subsequent cabling and jacketing to produce Cable-In-Conduit conductor by the Italian consortium ICAS (completed in October 2015). ENEA procured the TF coil casings manufactured by the company Walter Tosto.

The JT-60SA project is one of the three large projects covered by the Broader Approach agreement concluded between the European Atomic Energy Community (Euratom) and Japan.