F4E and AVS-Tecnalia deliver beam line components for MITICA

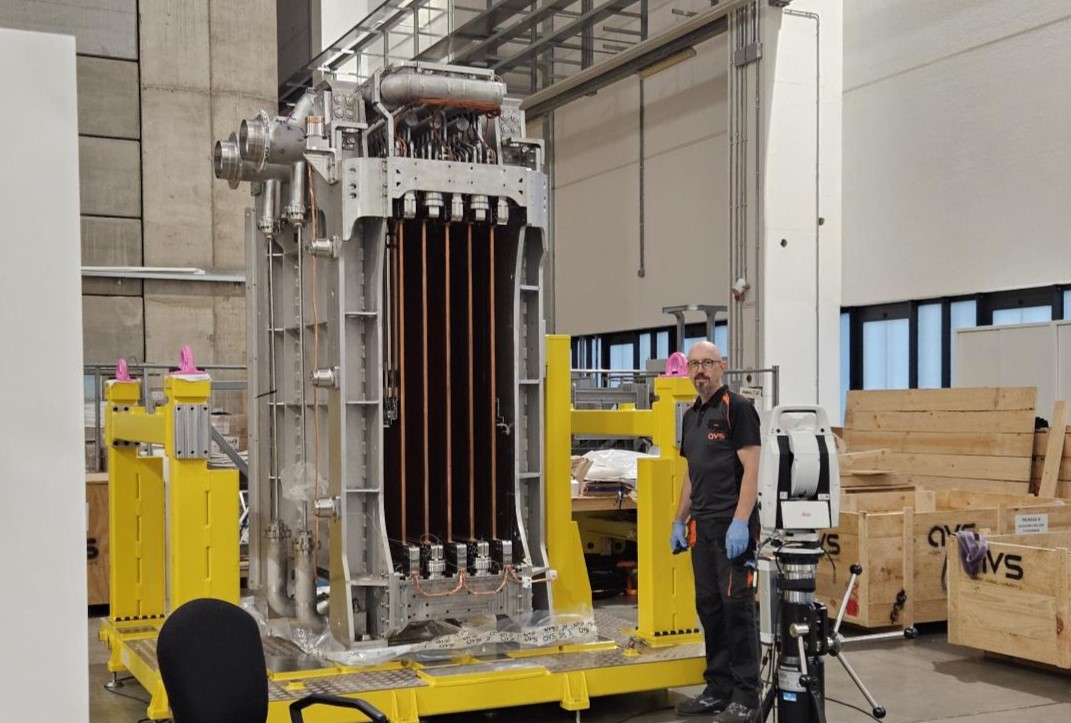

A technician from AVS stands next to the MITICA electrostatic residual ion dump. ©AVS

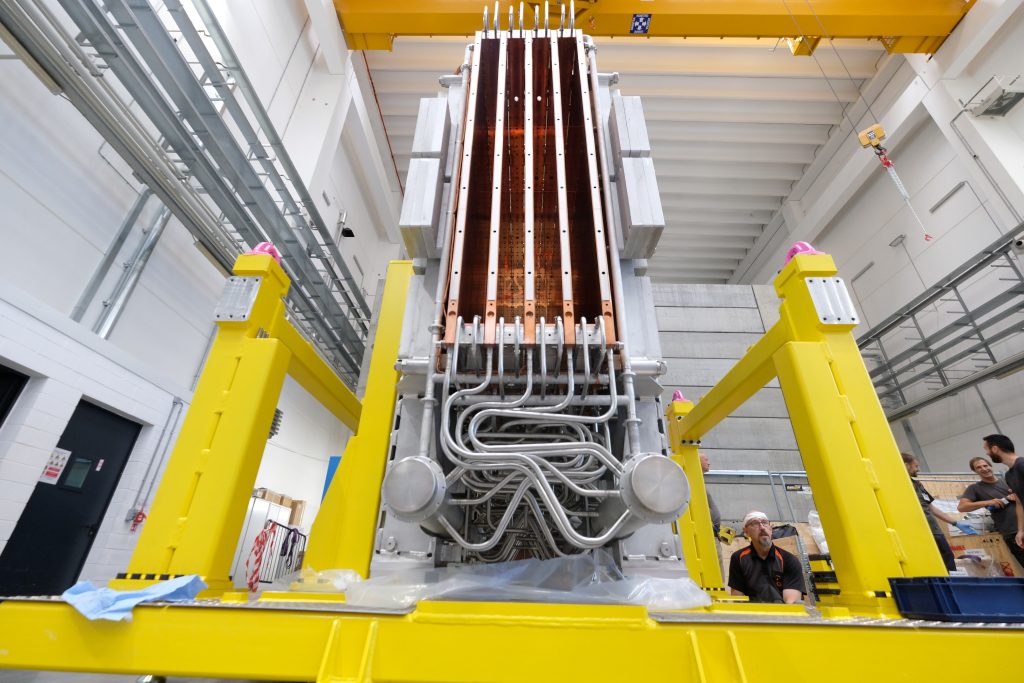

It was an exceptionally busy August at the AVS workshop in Elgoibar, an industrial town in the north of Spain. The technicians finalised the assemblies and performed all checks to the neutraliser and the electrostatic residual ion dump (ERID). These are two of the three components that Fusion for Energy (F4E) entrusted the AVS–Tecnalia consortium with in 2019. Together with the calorimeter, they will form the beam line components for MITICA, a real-size prototype of ITER’s Neutral Beam injectors — a pioneering testbed for one of the systems that will contribute to the fusion reaction.

How? ITER will use two injectors to help raise the temperature of the plasma up to 150 million ºC. They will each generate and accelerate an ion beam at very high energy, of up to 1 MeV. Subsequently, the neutraliser will remove the electrical charge of the particles and the ERID panels will capture non-neutralised ones, so the beam can penetrate the magnetic field. The calorimeter will then let the beam through when it reaches the right performance. Once inside the reactor, the particles will transfer their energy to the plasma by colliding with the ions and electrons in it.

The three components will be housed in a steel vessel –resembling a ship container, only bigger and more sophisticated, as it is designed to function under high vacuum. When integrated with the rest of components, the system will reach an impressive size, matching ITER’s unparalleled scale.

Precisely, the lack of precedents for an injector of that scale and power was the reason to set up the Neutral Beam Test Facility (NBTF), hosted in Padova (Italy) by Consorzio RFX. There, the MITICA experiment will help scientists investigate the physics and qualify the technologies to be deployed in ITER. Europe is in charge of providing most of the equipment for the prototype.

Back in Elgoibar, AVS specialists wrapped up manufacturing with visual inspections, leak tests and metrology checks. Next, they packed the neutraliser (12 t) and ERID (14 t) and shipped them to Padua. Once installed in MITICA, the Site Acceptance Tests confirmed the achievement: despite the novelty and the complexity, the concept turned into reality.

In fact, more than 2000 drawings detailed the vast number of sub-components and their multiple interfaces. “We needed to comply with very tight tolerances to ensure the safety and optimal performance of the beam line components, which will work in an environment at high vacuum and temperature”, explains José Miguel Carmona, AVS Head of Fusion and Beams Area.

Before moving into production, AVS and Tecnalia took steps to anticipate risks. For instance, they qualified more than 40 welding and brazing procedures. These were tailored to the different sub-components, as some presented thousands of joints, with dissimilar materials or irregular shapes.

Eventually, all technologies proved ready and the delicate assemblies met the demanding standards. The expertise of the supply chain, a sound project strategy and good technical criteria contributed to this success. But attitude played a big part too.

“Inevitably we had doubts when starting a first-of-a-kind production, but our enthusiasm was bigger. We put all our brainpower into it, sharing a one-team mindset with F4E and Consorzio RFX,” asserts Carmona. “Our partners were fully committed to this contract. Even when facing challenges or deviations, they found solutions with a proactive spirit”, confirms Antonio Masiello, Project Manager at F4E.

Now, the neutraliser and ERID will be stored in Padua, at the NBTF. The calorimeter, the last part of the MITICA beam line components, is expected by next spring, bringing the experiment closer to operation phase. “In the process, we are accumulating a great deal of know-how that will be invaluable for building ITER’s heating systems,” concludes Masiello.