F4E signs contract for the supply of ITER Pre-Compression Rings

The contract for the supply of nine Pre-Compression Rings (PCRs), among which three spares, that will support the ITER machine’s magnet system, has been signed between Fusion for Energy (F4E) and EADS CASA Espacio. The total budget of the contract is in the range of 12 million EUR and it is expected to run for approximately four years.

The key function of PCRs is to reduce the fatigue of the ITER machine’s magnet structures from the powerful electro-magnetic forces and consequently prolong their operation from ten to over twenty years. The signature of the PCRS contract marks another European milestone that will deliver the largest composite structures ever built for operation in a cryogenic environment. The work will be carried out in a centre of excellence located in Spain, which has a proven track record in field of composites for space applications.

The function of PRCs in the ITER machine:

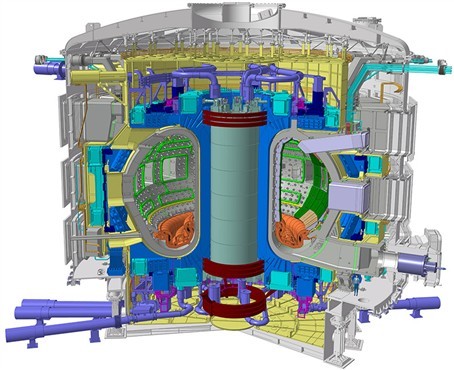

The ITER machine will operate with a system of superconducting magnets which relies on the Toroidal Field coils, the Central Solenoid, the Poloidal Field coils and the Correction coils (see ITER image).

Toroidal Field (TF) coils are “D” shaped coils whose core task in the ITER device is the confinement of plasma. PRCs are the keystones of the TF coils system and will be assembled to the top and bottom of TF coils in order to prevent them from deforming when the powerful magnetic field is created.

The size of the PCRs, their assembly and maintenance:

The basic design relies on 5 m diameter fibreglass composite rings with a cross section of about 300 mm x 300 mm at top and three at the bottom of the TF coil system. Three PCRs will be installed and loaded at the top and three at the bottom of the TF coil system and will apply a centripetal force equivalent to that of 3,000 tonnes on the top and bottom of each TF coil reducing their overall constraints.

In order to avoid the circulation of electrical currents and withstand high loads, the PCRs will be manufactured of fibreglass composite, where in every cross section nearly a billion of miniscule glass fibres will be glued together.

Their load will need to be maintained for the entire 20 years of ITER operation, while accommodating thermal shrinkages during cool-down/warm-up, cyclic forces, settlements and unexpected motions. Due to the limited access to carry out in-service inspection of the PCRs, in case there is a need for the replacement of the lower PCRs, it will be carried out by using one or more of three spare rings made available below the Tokamak in the cryostat.