Final spin for ITER Pre-Compression Rings

Pre-Compression Rings packed and stacked, CNIM, May 2020. Subsequently, they will be delivered to the ITER construction site. The components been produced through a contract signed between F4E and CNIM.

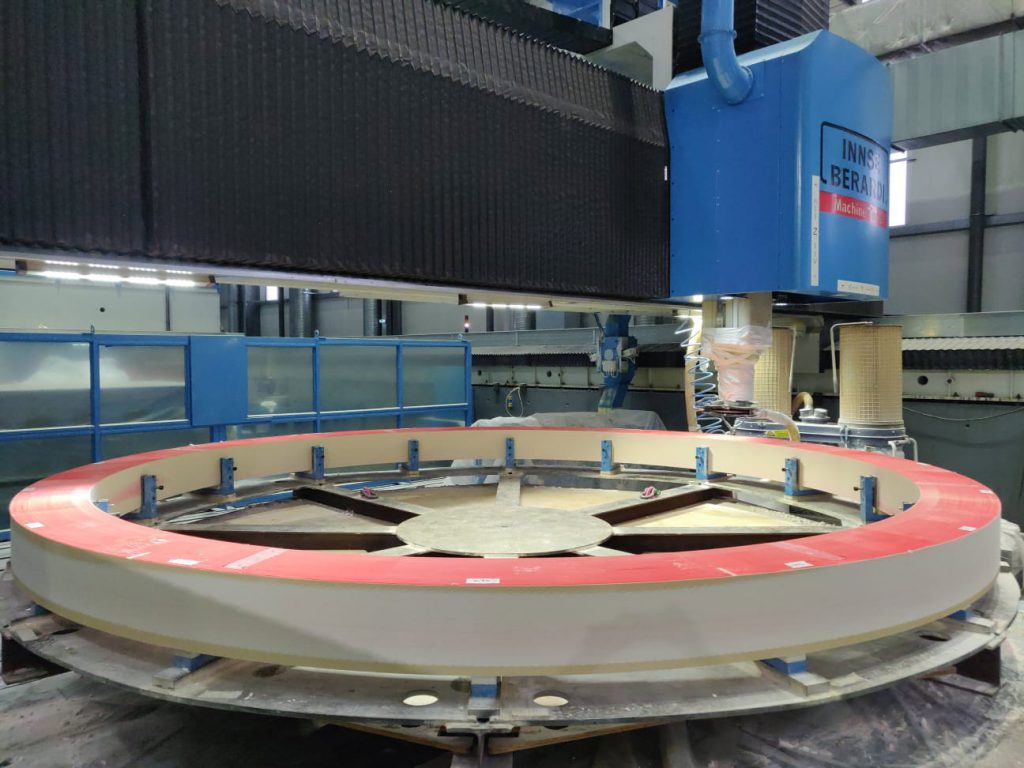

Six Pre-Compression Rings (PCRs) hold the key to the “wellbeing” of the ITER Toroidal Field coils. How? By taking the pressure off them. The massive D-shaped magnets will create a powerful magnetic cage to tame the super-hot plasma of the biggest fusion device. The PCRs can be described as a “stress-relief component” absorbing deformation and fatigue from the magnets of the machine. To be on the safe side, an extra set of three will be produced to have as spare.

Europe is the party responsible for their contribution to ITER. Through a contract signed between F4E and CNIM the fabrication of all nine PCRs is ongoing. Six of them have already been completed! In fact, they have been accepted and handed over to ITER Organization, which has the responsibility for the assembly of the device. For those involved in their production this is an important milestone because they have hit the magic number of the PCRs required to operate the machine. Basically, we are left with three more which are advancing well, and should be ready this summer. The machine winding the pultruded laminate—the main material of the PCRs— is ready for the final spins. The collaboration between F4E, CNIM, and Exel Composites, their subcontractor, has been fruitful delivering the components on time. After validating the fabrication technique, and passing the qualification tests, the companies demonstrated that they had acquired the necessary know-how to produce the PCRs on a steady pace.

Angela Hernandez, F4E Magnets, worked closely with Exel Composites (Finland) to follow the operations on-site. “The additional resources put in place by the company over the three shifts helped a lot, and any good practice picked from the fabrication of the first PCR to the next proved highly beneficial,” she explains. Through a deal signed between ITER Organization and CNIM, a test facility was set up in the South of France for the PCRs. Eva Boter, F4E Magnets, followed closely their fabrication and the final acceptance tests. “We worked as one team to get the production going. We delivered the components in-line with the specifications, and made sure they cope with even higher pressure than the one to experience in the machine. Six of them have successfully passed all tests and have been handed over to ITER Organization. Now, we are working on the remaining three and will plan later in the year their transportation to the construction site”.

Alessandro Bonito-Oliva, F4E Magnets Programme Manager, is the person behind the successful procurement strategy which enabled Europe to overcome technical hurdles and manufacture the PCRs on time. “By anticipating an alternative technology to the one initially selected for the fabrication of the PCRs, and through excellent collaboration between F4E, ITER Organization and the companies involved, a potential crisis became a success story. We have completed now six of the nine PCRs and we are on cruising speed for the remaining three. Excellent technical oversight and project management; strong commitment and flexibility helped us to achieve this remarkable result,” he explains.

“We have completed now six of the nine PCRs and we are on cruising speed for the remaining three. Excellent technical oversight and project management; strong commitment and flexibility helped us to achieve this remarkable result. ”

Alessandro Bonito-Oliva, F4E Magnets Programme Manager