Steel giants arrive on ITER site

Aerial view of the ITER construction site, Cadarache, March 2019 © ITER Organization

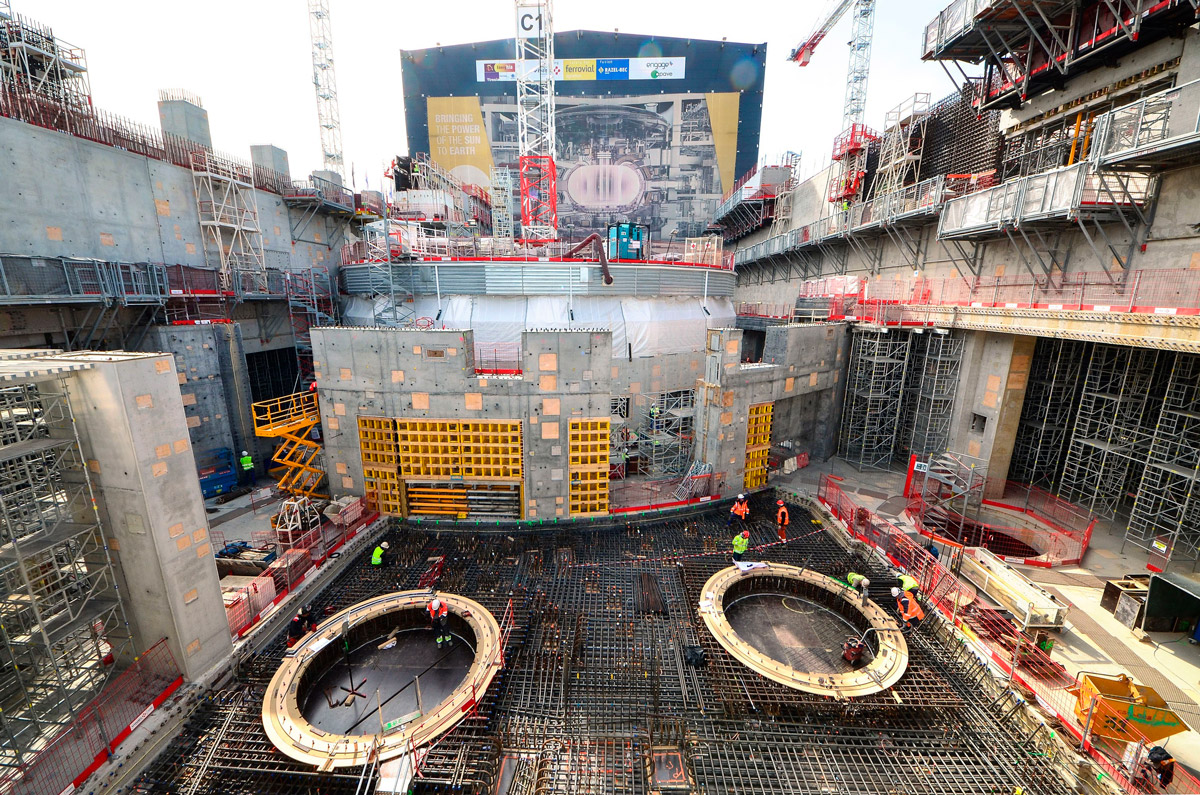

The morning shift comes to an end and a group of 160 workers involved in the construction of the Tokamak building is ready to go. Almost in perfect coordination they leave this labyrinth of concrete and steel wearing their hard hats, glasses, gloves and jackets to hand over to the next shift. Roughly 350 people are working round the clock during the three shifts. It has been a long day because there have been some new developments on-site: the first pieces of the 40 steel columns that will be erected to form the roof of the Tokamak building are here. They have been produced by Martifer, a company based in Portugal, working for the Vinci Ferrovial Razel-Bec (VFR) consortium responsible for the civil engineering works of the entire Tokamak complex. The first heavy pieces of steel reached Cadarache and literally touched ground a month ago. Their final position, however, will be 45 m above the ground floor of the Tokamak building.

Behind the impressive banner overlooking the main building of the ITER project are the massive cranes of the Assembly Hall. In a nutshell, the plan is to erect the roof of the Tokamak building at the same level of that of the Assembly Hall, pull down the banner and the “temporary barrier” –which is ready—

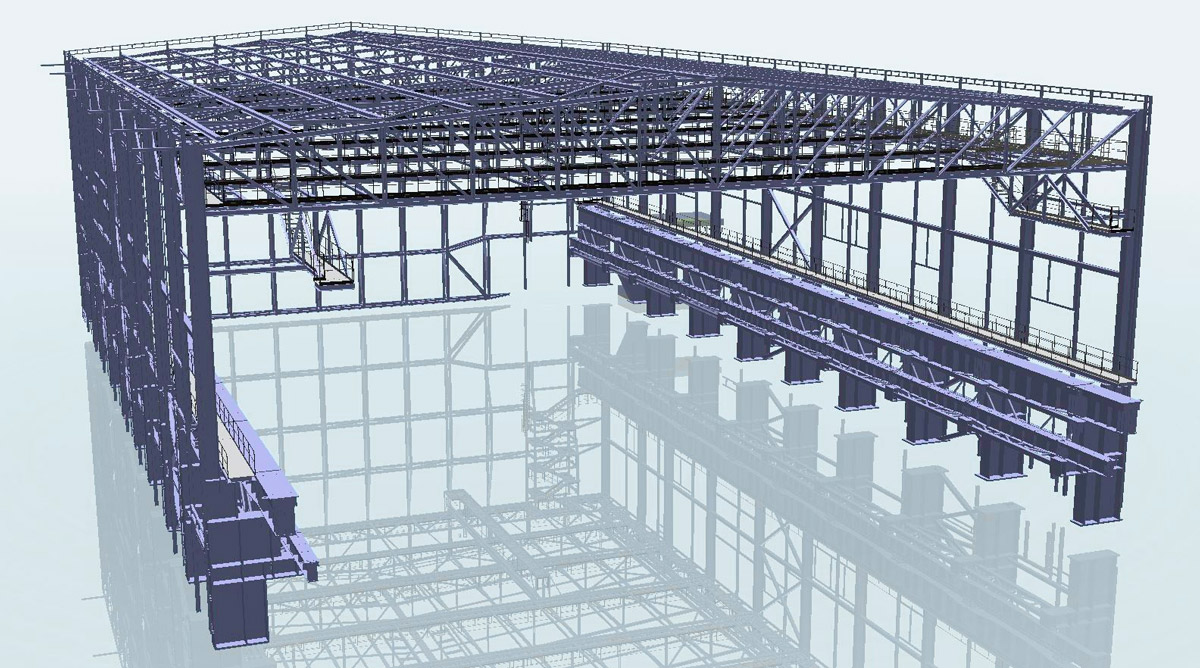

in order to let the cranes operate on both sides of the buildings so as to lift the assembled ITER components from one end and install them in the home of the machine. The steel structure (roof) of the Tokamak building will weigh approximately 2 000 t. It will be made of prefabricated elements, which will be lifted at 55 m high in autumn. The sequence is quite straightforward: the roof steel structure will be assembled in five modules on the ground, and then each of these modules will be lifted with a massive crane to be connected to the steel columns. Each column will be between 8-16 m high and weigh 20-30 t. Between October this year and February 2020 the activities will reach their peak and the lifting operation will kick off with the help of a dedicated crane.

“Parallel to the works advancing on each floor of the Tokamak building we will soon start working on the pre-assembly of the roof structure. We are monitoring closely the production of the pieces of equipment that will be part of this gigantic steel roof so as to complete this operation on time” says Romaric Darbour, F4E’s Deputy Project Manager for Buildings, Infrastructure and Power Supplies. “Subsequently, we will get ready for the spectacular lifting operation of the heavy chunks of steel and their installation piece by piece to create the Tokamak building crane hall as an extension of the Assembly Hall’s roof” he explains.

The slab of the Tokamak building’s top floors (levels 4, 5) are progressing with particular focus on the east and west wings. Let’s move to the lower floors of the building to find out what has been happening the last few months. The sandblasting of the bioshield has been completed and painting is almost finished. Meanwhile, F4E has handed over to ITER Organization the ground and will deliver the first floor of the Tokamak building by this summer. The workforces have been hands-on with the fabrication and installation of heavy equipment. Out of the 46 port cell doors, 16 of them have been concreted and 11 have been installed. And out of the 194 shielding and confinement doors, a total of 21 have been placed.

Last but not least, there has been progress with the infrastructure works and galleries. Works on the site are unfolding in parallel above and below the ground. A three-stage approach has been adopted to cluster works sequentially: 62% of the deep works (phase A)have been completed, 27% of medium works (phase B) have been successfully concluded and 8% of surface works (phase C) have finished.