Europe and Japan install a powerful section in LIPAc

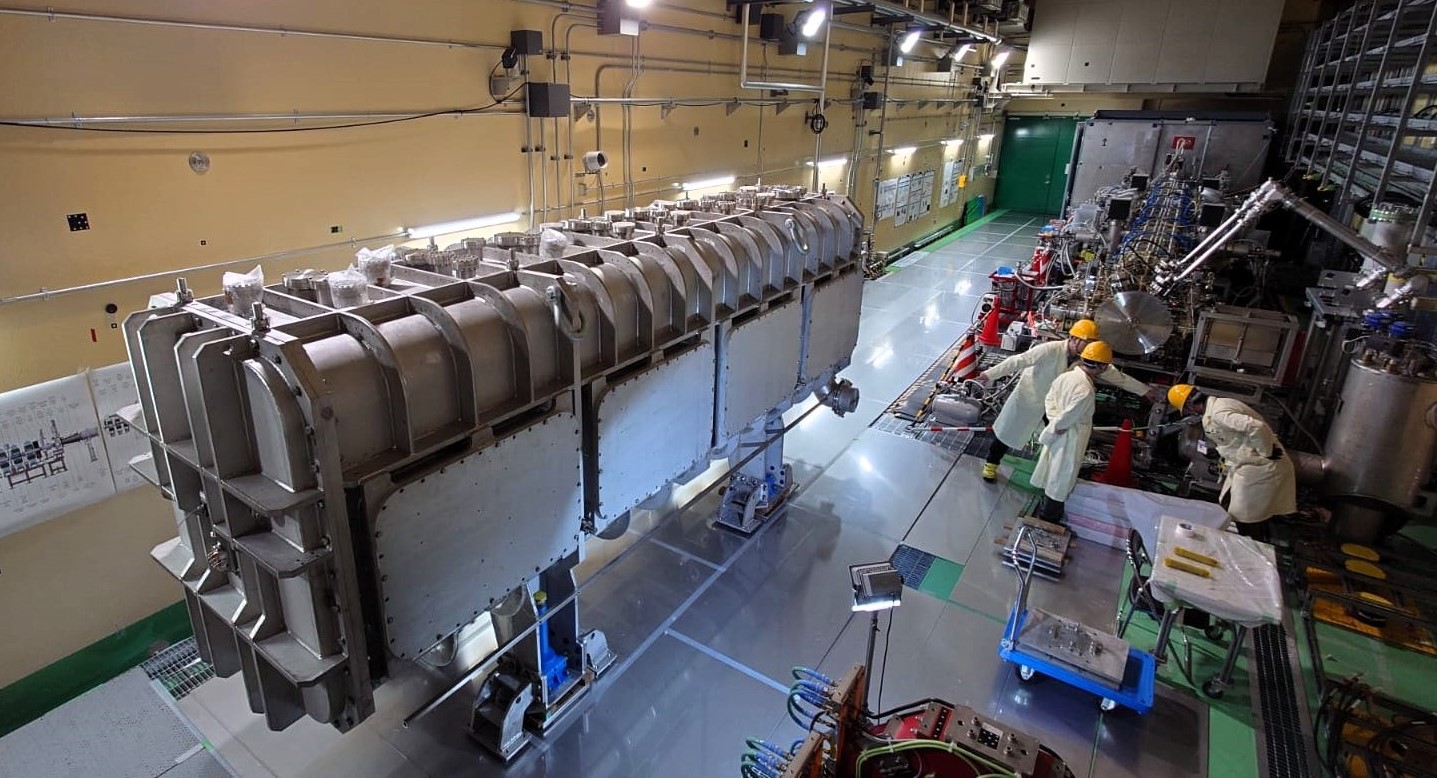

Japanese technicians during one of the operations to position the SRF linac in the beam line. ©IFMIF/EVEDA

The beam line of LIPAc is growing in length and power. The accelerator, built and operated by Europe and Japan, will soon reach its full configuration, unlocking unprecedented performances for a technology of its kind. The joint project, part of the Broader Approach collaboration, aims to pave the way for the future International Fusion Materials Irradiation Facility (IFMIF). At LIPAc, engineers and scientists are demonstrating how to recreate the intense radiation inside a fusion reactor by developing and testing a particle accelerator prototype.

Since the last operations campaign, the teams are focused on the final and most decisive upgrade of the machine. The Superconducting Radio Frequency (SRF) linear accelerator is being installed. This section, provided by Europe, consists of a string of cavities creating strong electromagnetic fields to accelerate the beam. Their force will enable LIPAc to speed particles to record energy levels: a 125-mA continuous-wave beam of deuterons accelerated up to 9 MeV.

To do so, the SRF line must operate at ultra-high vacuum and ultra-low temperatures (down to –269 °C). The system is contained in a 6-meter-long cryomodule, keeping its environment cold and clean. Its delicate assembly was completed last year, with technicians from Research Instruments working inside a clean room to integrate the components supplied by CEA and CIEMAT.

“We are dealing with an extremely sensitive component. The tiniest impurities infiltrating could degrade or even prevent its performance. A small misstep could force us to disassemble, setting back the project for months or years,” explains Janic Chambrillon, F4E engineer in charge of the SRF linac assembly.

The next task was moving the SRF section into the beamline. With such high stakes, a meticulous plan was rolled out with finesse. In March, the teams carried out the 500-meter transfer from the workshop to the accelerator vault. Despite the short distance, the commute for the 13-tonne cryomodule had to be as smooth as possible. Japanese technicians used a truck with a damper to cushion the ride and a powerful mobile crane to hoist it into the vault with the minimum impact.

Since then, the teams have been busy completing the assembly in preparation of the installation of the SRF accelerator section. After a sequence of adjustments, the system is now nearly in its final position in the beam line. In the coming months, they will wire up the components, test control systems and commissioning auxiliary systems like quench detection.

“We expect to complete the connection to the beam line next year. It will culminate a long process of thorough planning and teamwork between QST and F4E to optimise the schedule and mitigate technical risks,” adds Hervé Dzitko, Project Leader of IFMIF/EVEDA, leading the joint Europe-Japan team in Rokkasho (Japan). His team is also collaborating closely with IFMIF-DONES, the facility under construction in Spain. “The configuration including the superconducting linac has not been tested before. Its commissioning and operation it will give us a lot of valid feedback to complete the design of the DONES accelerator,” he stresses.

Ultimately, the technologies validated in LIPAc will help Europe and Japan tackle one of fusion’s greatest challenges: the quest for materials that can endure the intense neutron blasts inside large fusion reactors like DEMO.