Army of cryogenic tanks invades the ITER site

More tanks of the ITER Cryoplant departed from Fos-Sur-Mer, the industrial port of Marseille, and have been delivered to the construction site. The large pieces of equipment, measuring approximately 25 m, were stored in the facilities of the port until it was time to transport them to Cadarache. The countdown for the complex logistics operation, performed by DAHER, started a few weeks ago signaling the end of their long journey. Six of the tanks had crossed the sea all the way from China and one had come from Turkey. All components have been manufactured by Air Liquide, and their suppliers, as part of Europe’s contribution to ITER managed by F4E.

As various convoys of the voluminous equipment were crossing the streets and highway of Provence, many people stopped and stared. It was like watching a parade in slow motion where an army of white/beige containers was marching gracefully determined to conquer the site. As part of ITER’s cryogenic system they would play an important part in the operations required to cool down the machine to -269˚ C and store the gases. Basically, they would come to play after ITER’s heating systems raise the temperature of the fusion fuel to 150 million °C. An army of components designed to deliver cold power was getting ready to wage war against those that would produce fire.

Six gaseous helium (GHe) tanks have been manufactured to recover the gas from the machine and provide a buffer during operation. Each of them, measuring 25 m, will store roughly 800 kg of helium.One liquid nitrogen (LN2) tank has also been delivered, whose main task will be to work as a back-up in case there is a failure in the LN2 plant. The tank weighs 115 T and when it stores the gas it will be able to sustain a load of 340 T. The seven tanks have joined the two quench tanks, already delivered last year, raising the total of Europe’s cryogenic components on-site to nine. And in the next few weeks, the liquid helium (LHe) tank manufactured in Sweden, is also expected to reach the construction site.

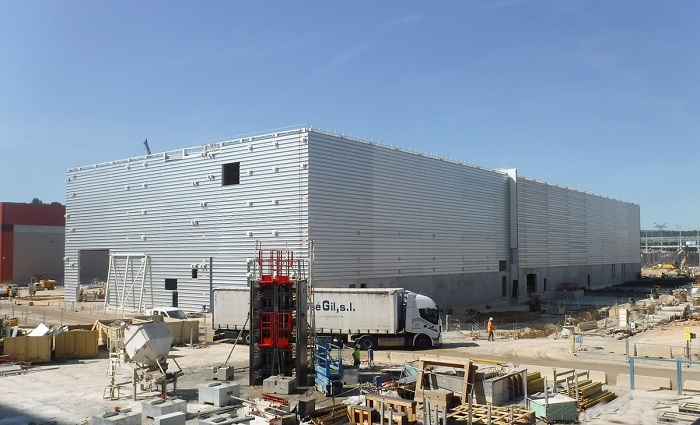

Meanwhile, the civil engineering works of the Cryoplant facility are being completed. The teams have concluded the works on the roof and are now focusing on the second layer of cladding. The helium plant Cold boxes are being installed, paving the way for the rest of the components to follow next early year. On-site, in the area where the massive tanks will be installed, the first layer of concrete has been poured and the embedded anchors, which indicate their exact positions, have been put in place.