Breaking new ground in electronics to cope with radiation

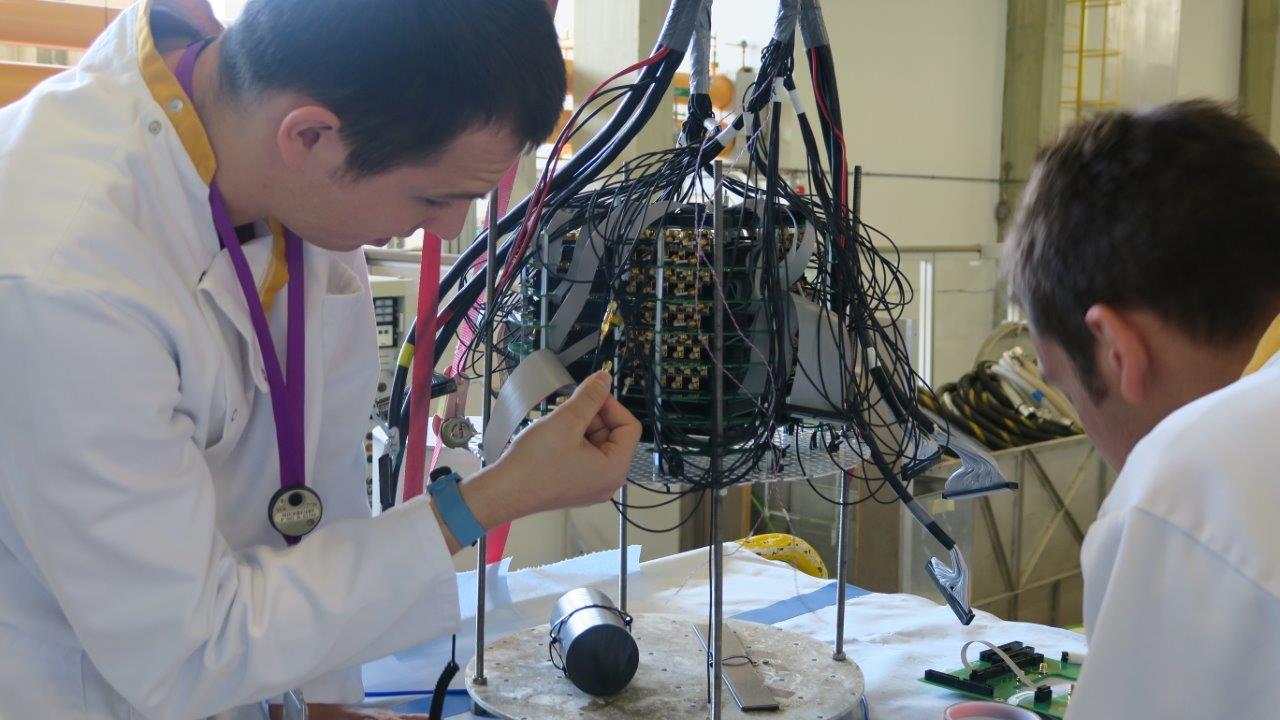

Experts from MAGICS testing the electronics that could be used in the core of the ITER machine. The works have been funded by F4E and result from the collaboration between Veolia Nuclear Solutions, MAGICS ©F4E

Europe organised a workshop to discuss the state of play in electronics and the progress required, in order to operate in the core of the ITER device during its maintenance, while the machine is shutdown. Off the shelf equipment is not always an option for a number of reasons. What’s currently available in the market is too bulky for ITER. The levels of precision required to monitor what is happening in the device is keeping experts very busy. The cameras used in fission are not matching the standards they aspire using in fusion. Therefore, there is a need to develop the right equipment for ITER’s remote handing system. And what better way other than a remotely-animated workshop to exchange best practice and learn from each other. More than 100 experts from F4E, ITER Organization, US, Japan, together with representatives from research organisations and ten companies connected online to discuss the latest breakthroughs in the field. For F4E, this is a subject of high importance because Europe is responsible for three of the ITER Remote Handling systems. Therefore, investing in the right technologies and getting industry involved at an early stage is of essence.

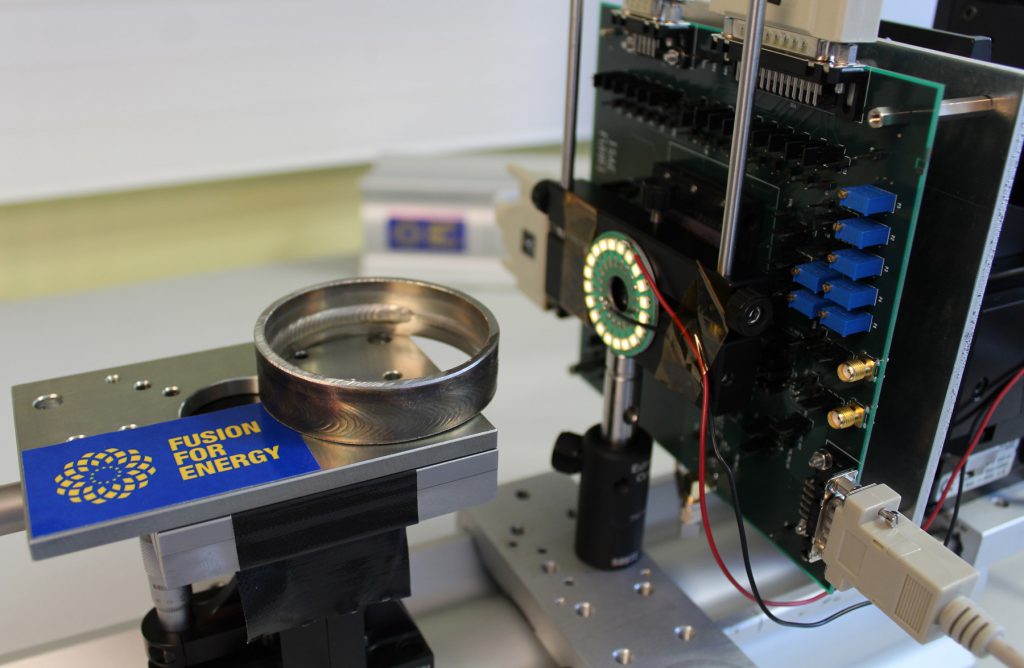

Due to the levels of radiation in the machine, engineers will not be able to access the ITER vessel to fix or replace components. Similarly, not all material qualifies to operate in the machine. Exactly for this reason, experts from the fields of remote handling, robotics, diagnostics, electronics, need to collaborate to produce the equipment that will help us maintain the fusion device from a distance. The presentations helped experts to capitalise on know-how acquired in the ITER Domestic Agencies. CERN was also invited to share results from projects funded in the field of radiation. Suppliers working directly with F4E such as Veolia Nuclear Solutions, MAGICS and ISAE-SUPAERO presented the latest developments showcasing rad-hard front-end electronics and rad-hard cameras.

The quest for suitable equipment has given an incentive to companies, collaborating with F4E, to develop electronics and the smallest cameras to sustain such levels of radiation. The achievement was presented to all participants. In Extenso, F4E’s technology broker, pitched the prototype to eight companies working in this field in order to explore the commercial potential. There is a clear business opportunity is on the horizon given the successful tests performed and the need for such type of equipment in the market. Company representatives were certainly intrigued by the breakthrough achieved. The possibility for B2B meetings was also offered so that various industrial partners discuss the prospect of further collaboration. Finally, the contribution of electronics to the evolving needs of the nuclear industry was also discussed.

Europe’s contribution to ITER offers companies the opportunity to increase their competitiveness and to transfer the know-how of fusion applications to non-fusion fields of work. Precisely for this reason, F4E invites industry to express its interest in using these electronics breakthroughs in their business. To all market intelligence units out there F4E has a clear message: seize this opportunity and explore its business potential.

“This fourth workshop has helped us make progress on many fronts. On the technical ground, it has shown very encouraging advancement in our technological developments for electronics and cameras, now much closer to industrial exploitation. On the integration side, we have been able to show technologies that can be shared across Remote Handling devices, not only those allocated to Europe. At ITER project scale, there are now also other colleagues involved, beyond Remote Handling systems. Finally, we have detected that there is a clear interest also in industry and other Big Science Projects, which is exactly what we were aiming at”, says Carlo Damiani, F4E Remote Handling Programme Manager.