Europe is ready to feed with current the MITICA experiment

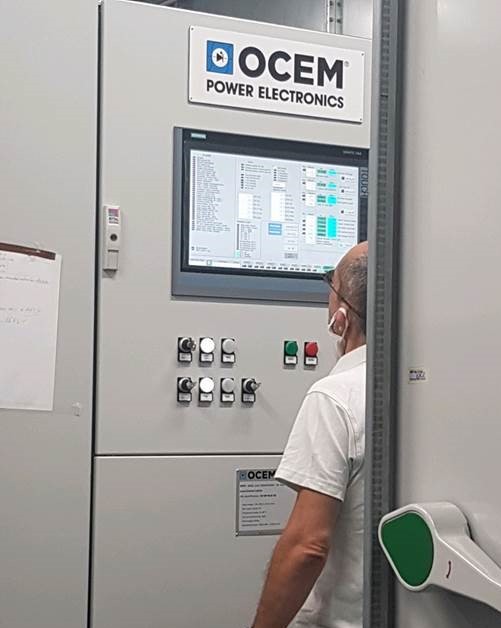

Performing the final site acceptance tests for the Ion Source and Extraction Power Supplies (ISEPS) in the Neutral Beam Test Facility, Padua, September 2020. Consorzio RFX is the host of the facility. The procurement for the components was managed by F4E. The equipment was manufactured by OCEM Power Electronics.

ITER will operate with the most powerful set of Neutral Beam Injectors (NBIs) ever used in a fusion device. With their help, the temperature of the super-hot plasma will rise. How? Once the negative ions are created, they will be accelerated at 1 MV and neutralised. Then, they will be injected in the core of the plasma in order crush with other particles. And as they collide the temperature will rise even more.

How easy is it to produce a kind of energy machine gun? Manufacturing first-of-a-kind equipment comes with a set of challenges. The thrill of breaking new technical ground by carrying out research means we are learning by doing. But what ranks much higher is the determination to deliver. In an international experiment that relies on contributors from different parties, co-ordination is of essence and without collaboration none of this can materialise. This is the thread that runs through the involvement of F4E, its contractors, Consorzio RFX, ITER Organization and ITER Japan in MITICA (Megavolt ITER Injector & Concept Advancement), a test facility hosting the first full scale ITER NBI in Padua, Italy.

Europe is working with several companies to produce its share of MITICA components. The Ion Source and Extraction Power Supplies (ISEPS) is one of them. Through a contract awarded by F4E, OCEM Power Electronics was entrusted with the manufacturing of the equipment. The production started in June 2017 and was completed in November 2018. On-site installation started shortly after and was successfully concluded in October 2019.

ISEPS consists of eight power supplies and auxiliaries producing 5 MVA in total. The equipment has been installed in a huge High Voltage Deck (HVD), a Faraday cage box produced by Siemens, measuring 12.5 m (L) × 8.4 m (W) × 9.6 m (H). With the help of cranes the power supplies were lifted nearly 10 m high and positioned on the two floors of the box. Muriel Simon, F4E Project Manager for Neutral Beam Power Supplies, who has been following this contract from the start, took the opportunity to highlight the importance of this achievement. “With the successful ending of the site acceptance tests of MITICA’s ISEPS, we have now completed our contribution to the power supplies of the Neutral Beam Test Facility. The experience and knowledge gained procuring equipment for MITICA will be invaluable as we shift the focus of the project activities to procuring similar equipment for the ITER injector.”

The site acceptance tests started in January 2020 but were put on hold due to COVID-19. A few months later all teams resumed operations and in September they were ready to perform the final tests, which were transmitted live for those not able to be physically present. Daniel Gutierrez Garcia, F4E Technical Officer, who stepped in the final year of the contract, needed to co-ordinate their execution in the midst of the pandemic. “No-one anticipated at the time the impact of COVID-19 on our work. We had worked out the dates to perform the tests in Padua and a few weeks later we had to comply with lockdowns. During that period we considered different plans given the circumstances, and this is how we ended organising a physical/virtual site acceptance test validating the equipment,” he says. Andrea Garbuglia, F4E on-site supervisor, explains how the pandemic triggered off a new working culture. “We had to limit the number of people present on-site and as a consequence we increased the frequency of our virtual meetings to keep everyone informed. To compensate for any delay, we used this time wisely to speed up the review of documentation in order to be ready on time. The experience we gained from the fabrication of the power supplies of the SPIDER beam source, the other experiment of the Neutral Beam Test Facility located in Padua, also helped enormously in the production of those of MITICA. But above all, it was the good team dynamics between F4E, Consorzio RFX, and OCEM that made this operation possible.”

Alessandro Tamburini, OCEM Project Manager, takes the opportunity to stress the importance of the work completed. “It is a great success for OCEM Power Electronics and it represents a small but important step towards the future of fusion energy. The chapter we started more than six years ago in Padua, with our involvement in both experiments of the Neutral Beam Test Facility, has come to an end. Our team achieved this result with sacrifice and enormous dedication. Not even Covid-19 was able to stop us. By the end of the year we will complete the documentation and formally hand over the equipment. The next step will be planning the installation of the equipment at ITER.”

For Tullio Bonicelli, F4E Programme Manager for Neutral Beam & EC Power Supplies and Sources, “the completion of the F4E contributions to the NBTF Power Supplies system represents the end of a long journey in an often unchartered territory. The competence and cooperative attitude of all our suppliers, Consorzio RFX, and ITER Organization, together with the dedication, resilience and problem-solving skills of the F4E team were key to overcoming any difficulties and reaching our goal.”