Europe signs multi-million contract to heat up ITER plasma

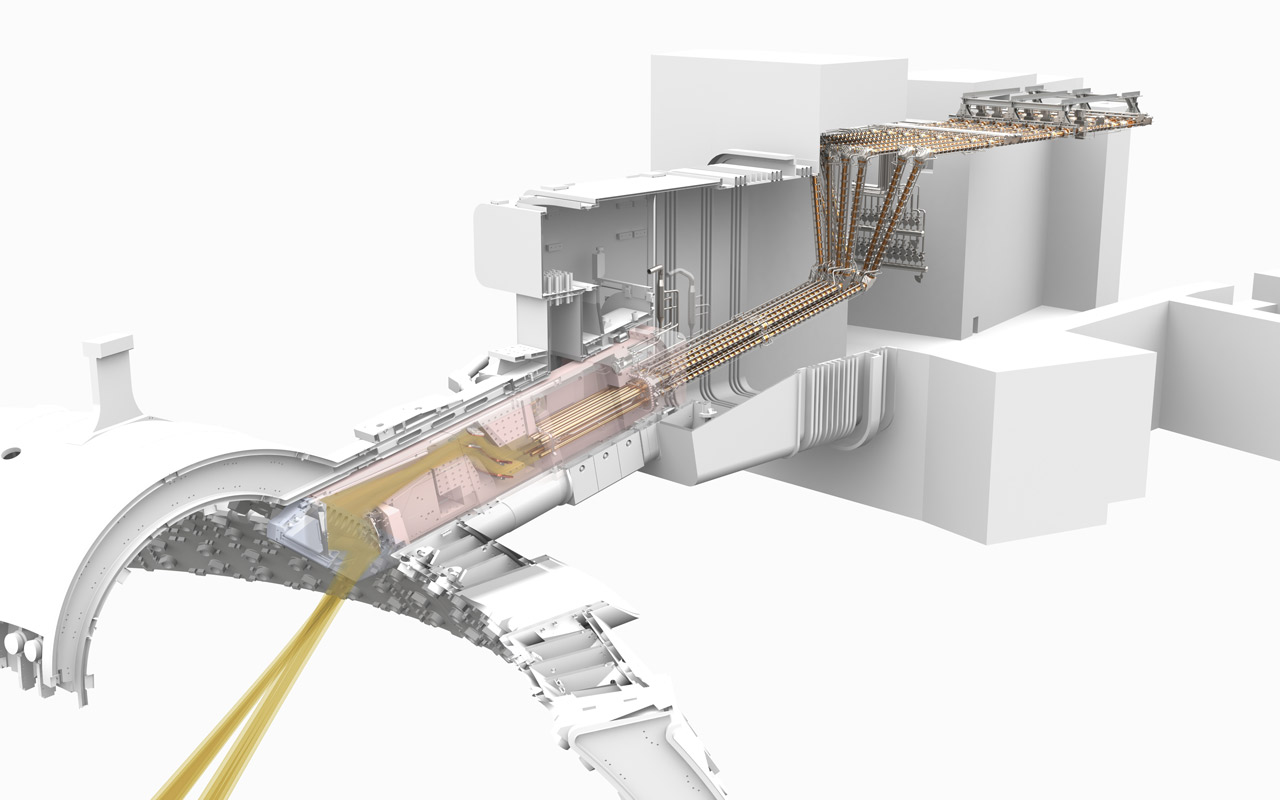

Illustration of one ITER Electron Cyclotron Upper Launcher and associated waveguide system, July 2022. © IDOM

One of the biggest challenges for scientists working in fusion is keeping the plasma burning for a sufficient amount of time. Any temperature fluctuations will require extra heating power, and any instabilities will need to be carefully monitored to keep it going. Otherwise, the hot gas will cool down and the fusion reaction will stop. The mission of the ITER Electron Cyclotron system is to deliver on both fronts.

The system is composed of gyrotrons (microwave power sources), waveguides (transmission lines), and launchers to inject the microwaves in the plasma, and heat it. F4E has signed a contract with the consortium of IDOM and ALSYMEX, for the design and manufacturing of four upper launchers and five ex-vessel waveguides. The cost of the works, which are expected to last six years, amounts to a maximum of 100 million EUR. The investment made by the EU through F4E will not only deliver technically complex components, but it will also help Europe’s industry to become more familiar with an essential technology for future fusion reactors.

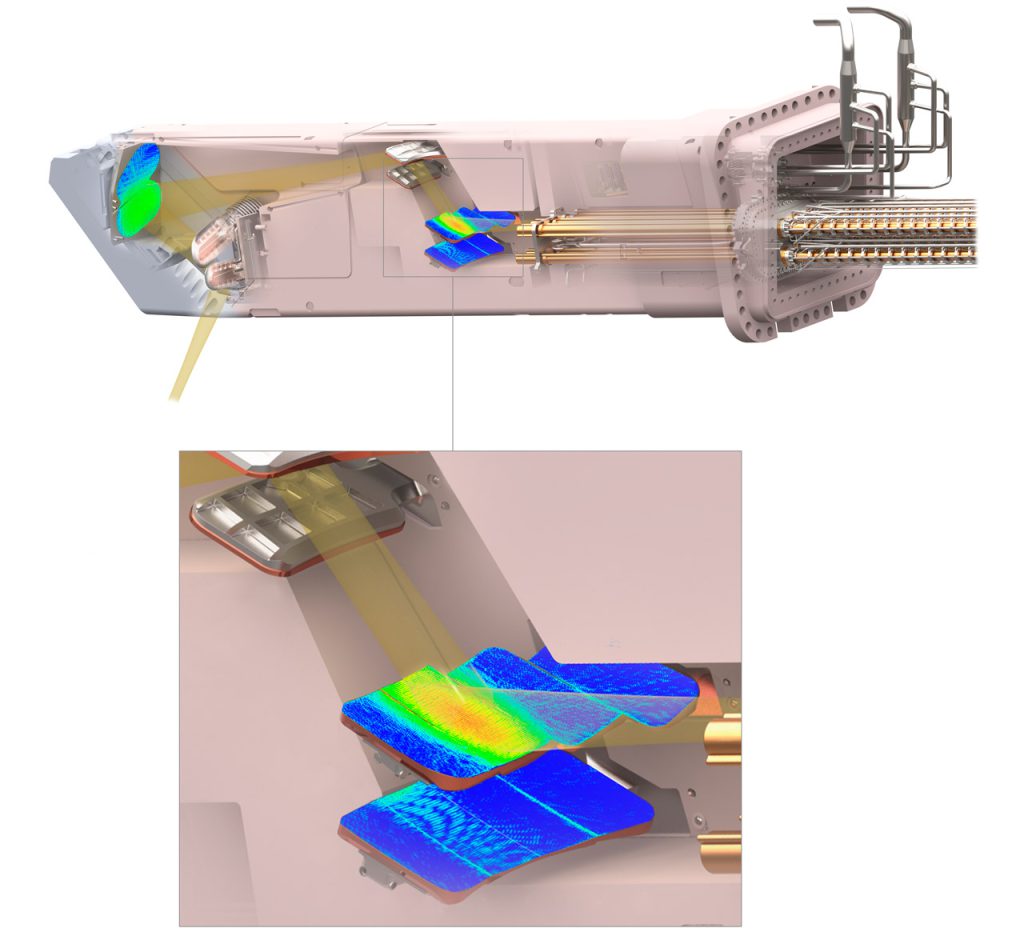

How will this work in practice? Each ex-vessel waveguide system will carry the microwaves to each upper launcher produced by Europe, except for the fifth ex-vessel waveguide, which will be connected to a different launcher delivered by Japan. Each upper launcher will then guide the microwaves to the plasma through transmission lines and mirrors, injecting up to 8 MW of power.

Much work in this field has already been conducted through other contracts signed by F4E and other suppliers. For instance, the system will rely on the use of diamond discs that will act as windows through which the microwave beam will enter the ex-vessel waveguide system but also block particles leaving from the vacuum vessel to the rest of the machine. These discs have been specially designed for ITER and are now under manufacturing. The mirrors are also a challenging component. They will be made of copper-chromium-zirconium, an alloy never used in nuclear components, to reflect waves better than other materials and cope with heat. Some of them will be part of a steering mechanism to direct the beam to a particular direction. The upper launchers and ex-vessel waveguides require expertise in mechanical, electrical, optical, materials and nuclear engineering, which makes their design and manufacturing an interdisciplinary challenge.

The consortium members state that “delivering such a complex and critical system for the first plasma operation of ITER is a challenging and exciting project. The strength of the IDOM-ALSYMEX consortium, the demonstrated experience of the project team and the close collaboration with F4E will allow us to make it happen.”

María Ortiz de Zúñiga, F4E Deputy Programme Manager of the Heating & Current Drive Programme for EC Upper Launchers, shares some thoughts. “The signature of this important contract, further strengthens F4E’s collaboration with IDOM and ALSYMEX in delivering components as part of the European contribution to ITER. As we embark on the design and production of these powerful heating systems, we will use this opportunity to foster know-how and expertise so that Europe’s industry gets ready to harness the energy of the future.”