Europe starts manufacturing ITER Torus and Cryostat Cryopumps

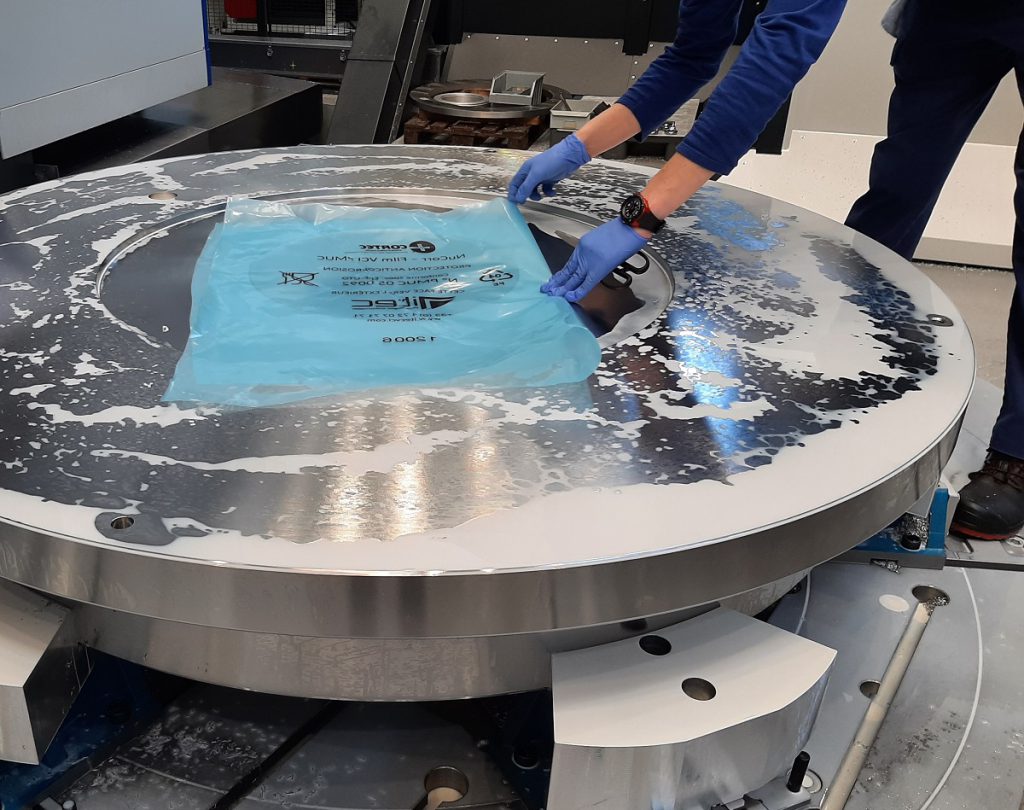

Two pump plugs in the workshop, not yet fully machined. These are the biggest components of the cryopumps. ALSYOM, France, July 2021.

Ensuring the proper vacuum conditions in the ITER Torus and Cryostat will be critical to perform the fusion experiment. The production of custom-made cryopumps to this end has already begun.

After a first successful Manufacturing Readiness Review (MRR) completed in January, the second and final one was performed in April, thus enabling the fabrication of all the cryopumps’ components. “Reaching this stage in the project required significant effort to qualify special processes and to ensure that the demanding specifications of the ITER project are met. These include cleanliness conditions for the high vacuum levels, tight tolerances, and nuclear safety requirements,” explains Francina Canadell, F4E Project Manager and Technical Responsible Officer.

The RI – ALSYOM consortium put a lot of work to conclude this MRR. Dr Michael Pekeler, Director of RI, tells us more about it. “It has been quite a challenge to finalise all the required documentation but we have reached this milestone due to the commitment and enthusiasm of our engineers and thanks to the excellent collaboration with F4E and ITER Organization. We are now looking forward to the production of the cryopumps, which has already started in our two companies. We are delighted that we can contribute to the success of ITER by supplying such fascinating high tech components.”

A total of eight cryopumps are being produced. Two of them will pump out the 8 500 m3 from the cryostat, reaching a high vacuum (10-4 pascals, a billionth of the atmospheric pressure at sea level). The other six will pump out the residual gas from the torus, a 1330 m3 chamber that will achieve an even higher vacuum (10-6 pascals, that is one hundred times less pressure than the previous one). The pre-production cryopump, which served to draw lessons for enhancing the final design and was delivered to ITER in 2017, will be left as a spare one.

“The project involves many processes that are advanced, such as hydroforming, or with record-breaking requirements, such as the machining of the sealing surfaces. Considering these technical challenges, the manufacturing stage has been reached in a very short time. I’m proud to be part of a team which made this possible!” states Yves Cartier, Sofren Nuclear Safety Officer providing support to F4E. 19 M EUR will be invested in the manufacturing of these 8-tonne components. The ITER Torus and Cryostat Cryopumps are expected to be delivered in 2022.