F4E joins new ITER Beryllium Management Committee

An ITER Beryllium Management Committee (IBMC) has recently been established and consists of representatives from the ITER Central Team and from Domestic Agencies involved in beryllium activities namely F4E, China and the Russian Federation. Its objective is to deal with the overall supervision of the applicable legislation and regulations and identification of all ITER activities involving beryllium.

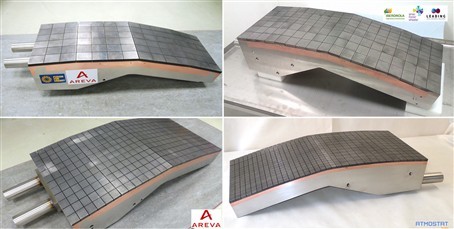

Certain components within ITER will contain beryllium, for example the Blanket First Wall which consists of 6-10 mm thick beryllium tile panels of 1 x 1.5 metres which are fixed to a bi-metallic support structure made from a 15-25 mm thick copper chromium zirconium (CuCrZr) alloy bonded using Hot Isostatic Pressing (HIP) to a 40-50 mm thick 316L (N) stainless steel backing plate – together these components form the Blanket First Wall panels. The Blanket is the part of the ITER machine that acts as a first barrier and protects the vacuum vessel, which is the heart of the ITER machine, from the neutrons and other energetic particles that are produced by the hot plasma. The First Wall consists of 440 panels, of which F4E will provide about half and depending on the location of the modules in the Blanket, different design parameters are necessary.

“Beryllium, widely used in aerospace and in telecommunications industry for example in copper alloys for electrical contacts in mobiles telephones, is an excellent metal to use in ITER’s First Wall. It has a low atomic number and therefore compatible with plasma operation, but at the same time presents good thermal and mechanical properties”, explains Patrick Lorenzetto, Project Manager for the F4E team dealing with the Blanket First Wall and the F4E representative in the IBMC. “When the ITER machine will be working containing a plasma that has a temperature of 150 million degrees C, the low atomic number of beryllium means that during plasma-wall interactions beryllium atoms go into the plasma, but does not dissipate much energy from the plasma enabling the plasma to stay enough pure and function for a longer period”, he adds.

Beryllium is however to be handled with care – its dust can in extreme cases cause lung disease. It is therefore vital to handle the First Wall panels and all beryllium containing components with care during their transportation from their manufacturing locations to the ITER site and during their assembly in the ITER machine. With the IBMC now established, its immediate task is to examine legislation related to beryllium safety requirements for the ITER site as well as research best practices in order to establish clear rules related to handling, the packaging of the components for transportation and the use of special safety suits by the workers who will transport and install the panels. The Committee will meet twice per year (the next meeting is scheduled in January 2016) in order to exchange information and implement and coordinate the safety activities.

“We aim to undertake every safety precaution necessary”, says Patrick Lorenzetto. “Indeed, we will use best practices from both the aerospace and defence industry, and also from JET who have now accumulated many years of experience”, he says.