F4E signs contract for first wall panel semi-prototypes

F4E has signed a contract for the manufacturing of a semi-prototype for first wall panels. The contract encompasses the manufacturing of one Blanket first wall panel semi-prototype component containing beryllium parts for which some of the critical technologies are only developed by a few European companies. The signing of the contract with a consortium consisting of Iberdrola Ingeniería y Construcción S.A.U. (Spain), AMEC Nuclear UK Ltd (United Kingdom) and Mecánica Industrial Buelna, S.L. (Spain), marks a positive milestone in F4E’s efforts to encourage European industry to develop their know-how in this specialised field of technology and widen the pool of available competence.

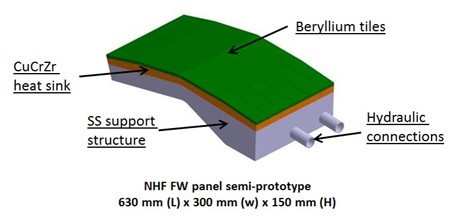

So what are first wall panels? They are 1m x 1.5m detachable elements which together with the shield block (a block of stainless steel on which the first wall panels are fixed) form the Blanket. The Blanket is the part of the ITER machine that acts as a first barrier and protects the vacuum vessel which is the heart of the ITER machine, from the neutrons and other energetic particles that are produced by the hot plasma. The First Wall consists of 440 panels, of which F4E will provide about half. Depending on the location of the modules in the Blanket, different design parameters are necessary. F4E is providing the Normal Heat Flux panels (the Enhanced Heat Flux panels will be provided by the Chinese and Russian Domestic Agencies). Normal Heat Flux panels are designed to withstand heat fluxes of up to 2 MW per m², whereas Enhanced Heat Flux panels can withstand heat fluxes up to 4.6 MW per m². The panels are made up of beryllium tiles which are bonded with a copper alloy and stainless steel using Hot Isostatic Pressing (HIP), a method that involves pressure generated by gas in order to compress the metals together homogenously from every direction. The use of beryllium in the manufacturing necessitates a specialised technology which is only carried out by a handful of European companies.

In order to minimise fabrication risks, it was decided to proceed step by step towards the fabrication of the series of panels, i.e. introducing the fabrication of semi-prototypes first and then manufacturing full-scale prototypes before focusing on the manufacturing of the actual panels to be used in the ITER machine. The semi-prototypes manufactured under the scope of this contract, will be one-sixth of the size of the actual panels. Fabrication is scheduled to start in February 2013 and work will be concluded in the first quarter of 2014. Following the completion of the semi-prototypes, the next step will be to produce a full-scale prototype, for which a contract will be launched during the first half of 2013. The contract for the series of panels to be used in the ITER machine will be placed in 2015.