Final Design Review for Blanket Cooling Manifolds completed

An important milestone for the F4E and ITER schedule, the Final Design Review (FDR) for the ITER Blanket Cooling Manifolds (BCM) has been completed.

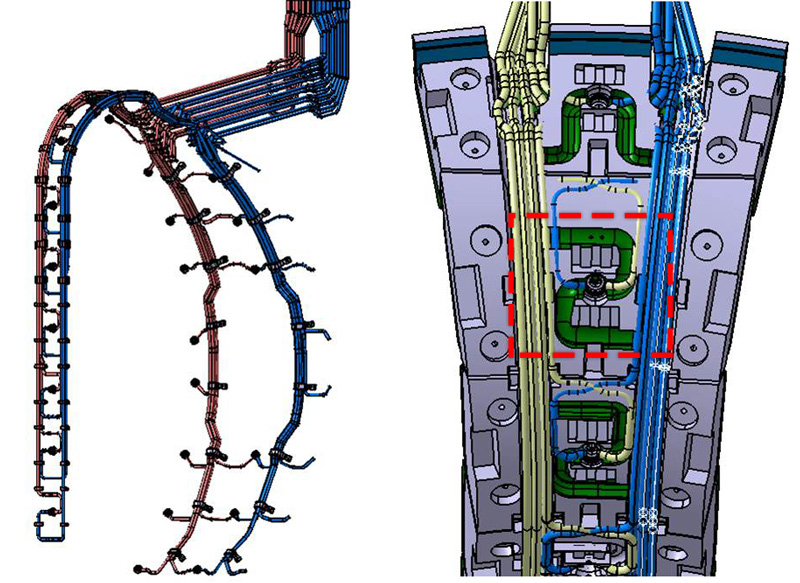

The blanket modules are the part of the ITER machine that act as a first barrier and protects the vacuum vessel, which is the heart of the ITER machine, from the neutrons and heat produced by the hot plasma during the fusion reaction. The cooling of the blanket modules is ensured by the Blanket Cooling Manifolds which are connected to the Tokamak Cooling Water System (TCWS) and provide pressurised cooling water to the Blanket system. The BCM system is based on the multi-pipe concept, i.e. it consists of bundles of separate stainless-steel pipes running inside recesses at the back of the blanket modules. In total, the pipes make up a total length of approximately 6.5 km and together weigh around 45 tonnes.

The FDR meeting was held in order to identify, solve and finalise outstanding issues on the Blanket Cooling Manifold and check that the design solution meets the ITER requirements. It marked the final stage before the Call for tender and the manufacturing of components begins. The FDR was led by an official review panel, appointed by ITER IO and chaired by Bradley Nelson, Chief Engineer of the US ITER Project Office. F4E and ITER International Organisation representatives in areas such as materials, stress analysis, safety, control and Quality Assurance took part. The conclusions of the panel were generally positive regarding the state of readiness of the BCM design. The only exception is the readiness of the support design, which is the object of an on-going analysis that will be completed in the coming months.

The launching of the Call for tender for the manufacturing of the BCM series is planned for early 2018. The signature of the manufacturing contract is foreseen by December 2018. The time of delivery of the BCM series will be staggered from 2022 until the end of 2023.