How to join the pieces of ITER components

Inspector checking vacuum vessel sector 3, poloidal segment 2 at Walter Tosto, Italy, April 2021.

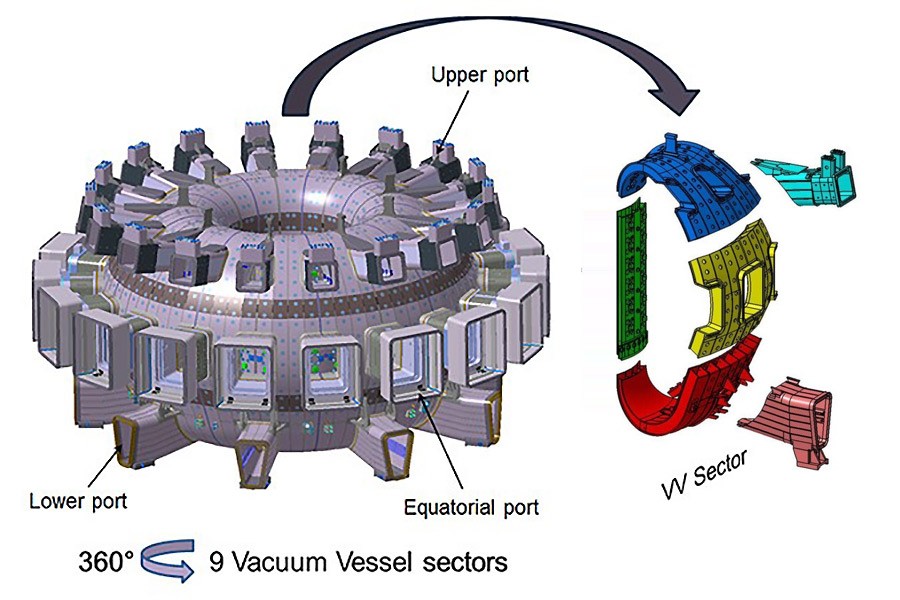

ITER is a massive jigsaw with millions of pieces in production as we speak. The challenging part, of course, comes when one tries putting the pieces together. This is exactly what will happen with the vacuum vessel, the part of the machine that will house the plasma. It is composed of nine sectors, which, in turn, are made of four segments. But here’s the tricky part: as there are small gaps between components, there is not a unique way in which these segments can be put together. So which is the best?

Virtual fitting is a simulation technique that F4E experts have developed to address this kind of situations. It is a strategy to mimic the assembly of the real components in a virtual environment. By simulating different alignment scenarios, experts can anticipate future problems and take informed decisions on which option is better to join the different pieces.

Without virtual fitting, the usual procedure consists of directly positioning the four real segments ready to be welded in the assembly frame. Experts then take measurements to ensure that everything is well aligned. Usually, some segments will need to be repositioned putting on balance the welding process to be followed and the final position of the different parts. This process is carried out until an acceptable solution is found, and takes time, as the components weigh over 100 tonnes.

The idea of developing a virtual fitting tool came from F4E Metrology expert Alessandro Lo Bue. He started to explore the possibilities of a commonly used programme in the field of metrology (SpatialAnalyzer®) in 2018. Since then, he has been building, together with Edoardo Pompa, SETIS Metrology Technical Assistant supporting the F4E Metrology Team, a methodology to perform virtual fitting with this software.

They have tried it successfully on two mock-up segments of the vacuum vessel and toroidal field coils (the D-shaped magnets that will confine the plasma). “The AMW (Ansaldo, Mangiarotti and Walter Tosto) consortium quickly endorsed the use of virtual fitting proposed by F4E. It was clear that this technique presents advantages to prevent unacceptable positioning of the components and therefore to save time. It helps project managers to minimise risks and have a precise control of the assembly. The collaboration with the AMW metrology experts has been really effective,” states Alessandro Lo Bue.

“In two hours, the computer file for the vacuum vessel can generate a scenario that includes more than 1 million surveyed points, with 30 interfaces like welding lines, housings, port stub extensions, etc. Depending on which features you consider more important in the alignment, the software changes the proposed configuration,” explains Edoardo Pompa.

They have been using this technique for the sector 5 of the vacuum vessel since November 2020. It will also be used during the welding process of the sector to see how the component changes its shape due to welding. Experts can stream the real data in the virtual scenario to flag a warning when the permitted margin of tolerance is about to be exceeded. For sure, this methodology is here to stay and will be used in the fabrication of other ITER components.