ITER Cask and Plugs Remote Handling system gets ready for final design

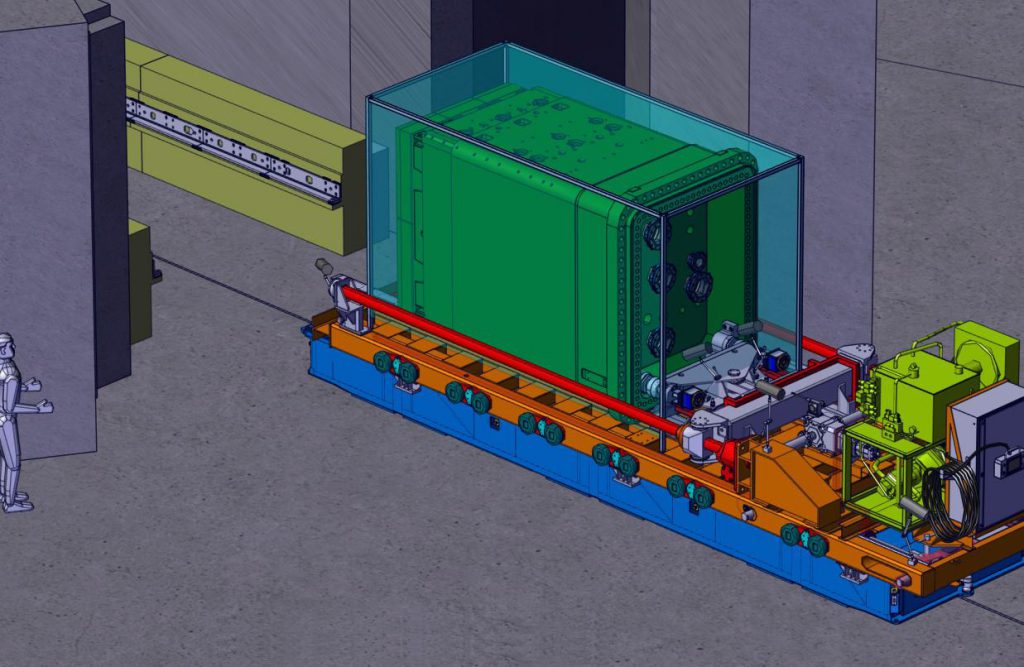

CAD illustration of the ITER Cask and Plug Remote Handling System to be procured by F4E. The tooling is approaching the port plug insertion into the vacuum vessel. Veolia Nuclear Solutions (VNS) has prepared the illustrations for the Preliminary Design Review of the system.

Remote Handling will help engineers to transport, maintain and replace heavy ITER components, weighing up to 50 t, which will be exposed to radiation in the core of the machine. A sophisticated system of man-in-the-loop robotics will be rolled out to perform these tasks with extreme precision. The heavy components will be lifted from the vacuum vessel to be stored in adjacent buildings. Europe is responsible for the production of four out the six remote handling systems deployed in ITER.

Each system needs to go through several steps to get manufactured. The Preliminary Design Review (PDR) signals the first stage of maturity. Its aim is to bring together engineers from various technology areas that will use this system (so-called “clients”), contractors that will be involved in the production, and external experts, who all together perform thorough analyses of the specifications and suitability of the preliminary design.

The PDR of the Cask and Plugs Remote Handling system addressed those cask units that will perform assembly tasks in the ITER machine before first-plasma. The review was organised by F4E and was split in two parts. During the first part, Veolia Nuclear Solutions (VNS), contracted by F4E from February 2019 till September 2020, presented the main features of the design and how it would meet the requirements. During the second part of the review, after having carefully analysed all documentation, questions raised by the reviewers were clarified and discussed in detail. Currently the F4E team is going through the last wave of comments made during the final meeting in order to commence the final design early next year.

Darren Locke, F4E Project Manager for Cask and Plug Remote Handling System explains, “This important milestone was achieved with a very collaborative spirit between ITER Organization, Fusion for Energy, VNS and its sub-contractor. We will continue using this successful approach as we move to the critical Final Design phase for the manufacturing of this assembly tooling.”

What is role of the Cask and Plugs Remote Handling system (CPRHS)? The transfer to and from the machine of the equatorial and upper port plugs will be carried out with the help of massive double-door containers known as casks. According to current estimates, 15 of these casks will need to be manufactured and in their largest configuration they will measure 8.5 m x 3.7 m x 2.6 m, approaching 100 t when fully loaded. These enormous stainless steel “boxes”, resembling to a conventional freight container, will be remotely operated to move between the different levels and buildings of the ITER machine. A mix of technologies consisting of remote viewing, navigation, sensors, actuators, hydraulics and electronics will be used.

Due to the fact that the ITER Remote Handling Room will not be available during the initial assembly phases of the machine, Europe’s engineers are fast-tracking a simplified version. The first assembly casks will be able to operate in a more versatile way. Lessons will be drawn for the design of future casks which will also comply with radiation requirements for the second phase of the ITER plasma experiments. Following the successful completion of the PDR by VNS, Ansaldo Nucleare will take over the reins to develop the final design in close collaboration with CNIM, responsible for the corresponding support rails.

Carlo Damiani, F4E Remote Handling Programme Manager, explains the importance of this milestone and the steps to follow. “With the successful completion of this Preliminary Design Review, we have now completed the PDRs for all European remote handling systems—this is a remarkable achievement. At the same time, we need to push the CPRHS project on a fast track to deliver the cask units at the right moment in order to allow the completion of the assembly of ITER and to be ready to produce the first plasma.”