ITER Remote Handling experts discuss mix of technologies to cope with radiation

The engineers involved in ITER’s Remote Handling system face several challenges: first, they have to develop some of the most futuristic pieces of equipment that will operate using virtual reality and man-in-the-loop robotics; second, although ITER is by far the biggest fusion device, space is an issue because there is a lot of tooling which needs to be neatly installed; third, due to the levels of radiation in the machine, all maintenance needs to be carried out remotely and the equipment needs to fit for this environment; and last but not least, this is a community of experts entering unchartered territory. Nothing like this has been tried before.

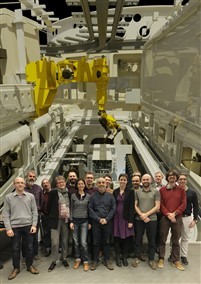

Once a year all experts from the ITER Domestic Agencies involved in Remote Handling systems, together with the companies and laboratories manufacturing the equipment, meet to discuss the overall progress and exchange information. The first of these workshops was organised by F4E, the second by ITER Organization. In November 2018, Europe took the initiative to plan the third workshop during which close to 60 participants met virtually to discuss the latest progress in radiation tolerant technologies.

Laura Mont Casellas, working as Technical Officer in F4E’s Remote Handling systems, was responsible for the workshop. “We thought of presenting the progress we have made so far in the field of rad-hard CMOS cameras which are suitable for the ITER environment and will allow us to see inside the machine. Due to the space limitation we face, miniature cameras are being developed which will be installed on inspection tooling,” she says. The progress results from years of intense collaboration between F4E and various companies, universities and laboratories. Magics, an SME specialised in rad-hard technologies, has designed the electronics integrated circuit chip prototype. Oxford Technologies, part of Veolia, has developed different sub-system mock-ups by bringing onboard the expertise of ISAE, Toulouse, for the image sensors. CEA-DAM has been involved in the illumination system, and the Jean Monnet University Saint Etienne for the optical system. The demonstration cameras have been successfully tested in Belgium’s SCK-CEN at different levels of radiation. Next, Oxford Technologies and ISEA will develop an image sensor prototype to be integrated into future industrial nuclear cameras.

The electronics required in Remote Handling was the other subject addressed. F4E has been pushing for a smart solution given the fact that cabling must be kept to a minimum. How can the “brain” of movers and its circuit be neatly installed? Magics and Oxford Technologies, part of Veolia, have been collaborating to develop a multiplexer –in simple words a compact box of electronics — which is able to reduce the number of cables needed for the movers to carry out maintenance works in the machine. Carlo Damiani, heading F4E’s Remote Handling systems, explains that “Europe presented the progress of the R&D financed by F4E because we plan using it in the components we have to deliver. On top of that, it could be of interest to them other ITER Parties and their suppliers. For instance, companies are eager to learn more about the progress of the work in case it finds its way to future applications they are designing.”

Last but not least, the workshop offered the possibility to Europe and Japan to inform participants on the radiation test results on commercial off-the-shelf components for the ITER In-Vessel Viewing system and the ITER Blanket Remote Handling system respectively.