JT-60SA Tokamak getting cooler every day!

JT-60SA, the largest superconducting tokamak in the world until ITER enters the scene, is on its path to start operations. Following assembly completion in March 2020, the Japanese and European joint team is now preparing for the so-called “first plasma”.

Tokamaks are complex fusion devices that do not possess a magic “ON/OFF” button in the middle of the control room – turning a tokamak on is a long process, which involves many precise and careful steps. JT-60SA, located in the Japanese town of Naka north of Tokyo, is now undergoing some functional tests, known as integrated commissioning, with more than one systems being tested simultaneously, in addition to the commissioning of individual systems which has already been successfully completed.

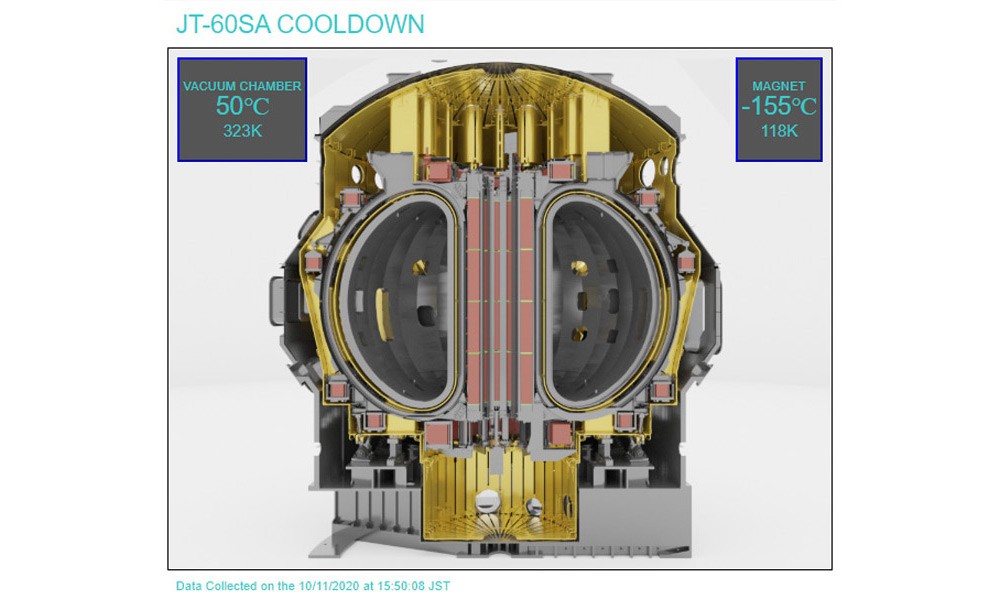

The process kicked off with the evacuation of practically all air from the vacuum vessel – the stainless steel donut-shaped “bottle” which will house the superheated plasma – and the Cryostat, which surrounds the vacuum vessel and superconducting magnets and ensures a vacuum to provide thermal insulation for the ultra-cool environment. Thanks to the excellent preparation, only a few minor leaks were detected and easily repaired. The successful vacuum pump down took about three weeks to complete, and paved the way to the current phase of slowly cooling the magnets to bring them down to their operational temperature of 4 degrees Kelvin (- 269° C). This phase started on 10 October 2020 and is expected to last several weeks as the magnets would need to go from the initial room temperature of 300° Kelvin (27° C) progressing at an average rate of half a degree per hour, although sometimes the process is briefly stopped for checks. A complex system of sensors spread inside the cryostat keeps a continuous eye on the gradually lowering temperature. To check the current temperature of the vacuum chamber and the magnets as they slowly cool down, click here.

As in all tokamaks, the massive magnets of JT-60SA would need to reach their operating temperature to achieve maximum superconductivity, necessary to produce the magnetic fields to initiate, confine, shape and control the hot plasma inside the vacuum vessel. The cooling down is performed through slowly circulating purified cold helium inside the magnets. Once the magnets reach the desired temperature, the team will proceed to heating up the vacuum vessel to 200° C to drive out moisture and any possible residual contaminants. Energising the magnets by passing an electrical current through them will come next. This is a critical operation, which will first be performed on each magnet separately, before doing it for the whole group together. The final step, before injecting hydrogen for making a plasma, would be to test the Electron Cyclotron Resonance Heating (ECRH) system, which heats the electrons in the plasma with a high-intensity beam of electromagnetic radiation, to the temperatures of over 200 million °C. The magnets will remain cool during all this time and on stand by for the first plasma, foreseen for spring 2021.

Sam Davis, one of the F4E Technical Officers in place in Naka, has been following the integrated commissioning since the completion of the assembly: “this is certainly an exciting time for me to be able to witness first-hand the whole process of bringing the tokamak to life. And although minor issues do pop up from time to time, the extremely thorough Japanese team has been able to resolve them”.

Almost twelve years after they started their collaboration under the Broader Approach Agreement, Europe and Japan have taken an important step in the development of fusion energy by completing JT-60SA and now preparing it for the first experiments. Although this tokamak is almost five times smaller than ITER in terms of plasma volume, it will initially be used as a proving ground for ITER, as the two devices are highly complementary in many areas. It will afterwards serve the development of following generation of fusion. The National Institute for Quantum and Radiological Science and Technology (QST, Japan) and Fusion for Energy (F4E, Barcelona) are the implementing agencies for JT-60SA with the responsibility for the manufacturing of components, the assembly and the commissioning of the device.