Paving the way for assembly of Europe’s first vacuum vessel sector

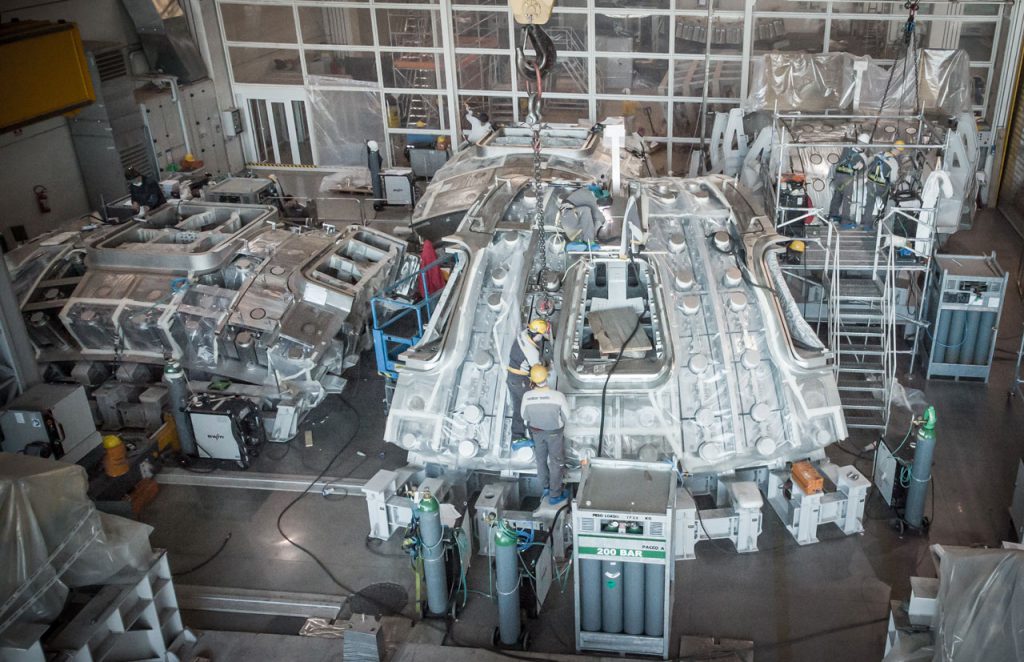

Final machining of segment 3-sector 5 of Europe’s contribution to the ITER Vacuum Vessel. Works performed at Walter Tosto, Chieti, Italy, February 2021.

The pieces are finally coming together. The first of the five vacuum vessel sectors managed by Europe is entering the phase of assembly. Under F4E’s supervision, the consortium consisting of Ansaldo Nucleare, Mangiarotti, Walter Tosto (AMW), supported by an extended network of sub-suppliers located in France, Germany, Spain, has been working relentlessly to meet this critical moment. One by one, the four segments that make one sector will be assembled to create another partition of the vessel that will house the biggest fusion reaction. To mark the significance of this achievement we highlight some of the complexities our engineers had to face and spoke to companies and F4E staff located in different production sites.

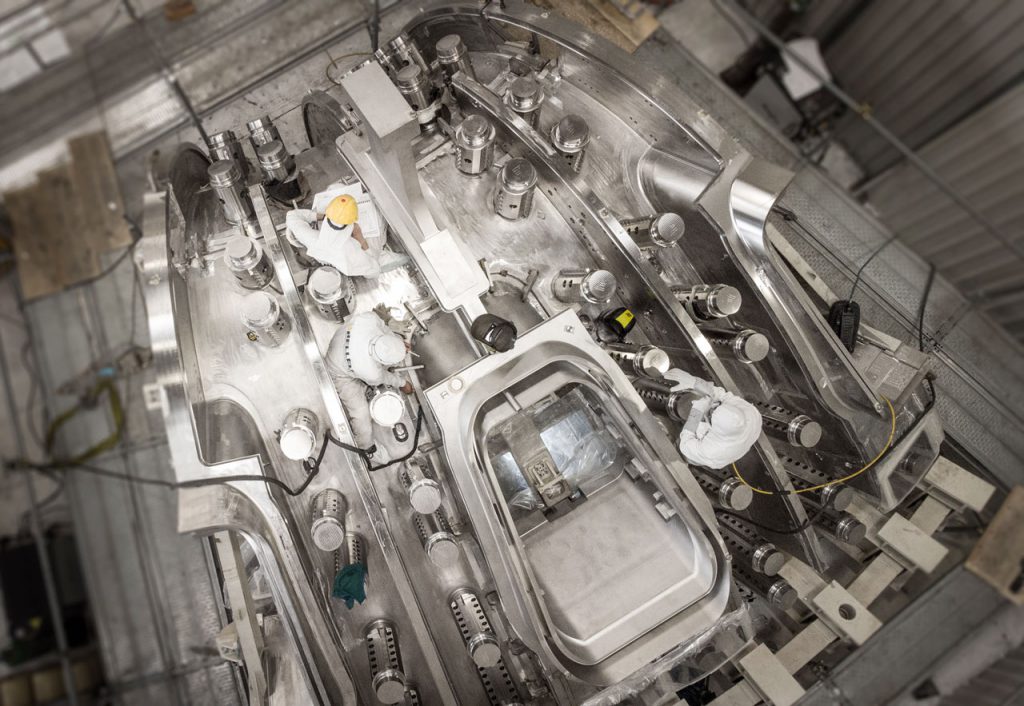

The design of the ITER Vacuum Vessel was developed from scratch mainly because none of the vessels used in other experiments were suitable for ITER. Building on previous know-how undoubtedly helped, but this first-of-a-kind component presented a new set of challenges all together. Its geometry and fabrication proved to be far more complex than originally thought. Each of the sectors and have particular specifications, and even the segments of the same sector, adding layers of complexity in their manufacturing. This massive shell made of stainless steel, structured on two walls, needs to comply with high standards set by the French Nuclear Safety Authority because it needs to withstand the levels of radiation resulting from the fusion reaction. Last but not least, it counts an impressive amount of welds— roughly 1 km/sector—also performed through electron beam welding to minimise any distortions.

And as if these issues were not enough to make its production seem like walking a tightrope, COVID-19 came to impose new rules and restrictions. The companies involved ensured a steady and safe flow of operations in order to mitigate risks and delays. “Staying focused, adapting to the challenges along the way, developing contingency plans and nurturing a good team spirit helped us reaching this point. Our industrial partners and the good collaboration with ITER Organization and the other ITER members contributed to this successful outcome” explains Cristian Casanova, F4E Vacuum Vessel Programme Manager.

Sector 5 will be the first that F4E will deliver to ITER Organization. At Monfalcone, north of Italy, where Mangiarotti is manufacturing two of the segments (1 and 4), there is feeling of anticipation for the start of assembly as they are also expecting later in the year segments (2, 3) from Walter Tosto, Chieti, roughly 150 km away from Rome. The segments will be welded following a specific sequence (1-3-2-4) in order to click together. It is envisaged that by mid-March the operations will start with segment 1. The assembly room is ready and the tooling is in place to start bit by bit the operations.

Andres Dans Alvarez De Sotomayor, F4E’s Technical Officer, is based in Mangiarotti where roughly 150 technicians are involved in the works. He has seen segments 1 and 4 coming all the way from a mere illustration to a solid component. “I still recall the early days when we concluded the design of the vacuum vessel sectors, prepared the procurement strategy, launched the tender and the qualification of suppliers. It has been a long journey. Since then, we have manufactured the equipment, conducted compliance tests and now we are heading for assembly. This gives you a sense of how far we have come.”

Max Febvre, F4E Manufacturing Project Manager, based in Chieti, is closely following the production of segments 2 and 3 of sector 5. He has seen how the component has evolved over time. “If I had to choose one technical operation which stood out it would be the installation of the outer shells, the external barrier of the vacuum vessel, which together with the inner shells, hold the shielding plates- the metallic cushions that offer more rigidity to the structure of the component. The amount of work we have put to complete this task is impressive. When we start assembling the segments of the vacuum vessel, we begin from the inner shell to the outer shell. When we reach this point, the equipment is so densely welded and compact that any inspection seems like mission impossible. We had to use ultra sounds to check every weld one by one. In terms of project management, we learned a lot from one another. With time, we drew good practice which we transferred from one factory to another, improved repair methods and started to exchange more information.”

Gianfranco Savoldi, Project Director of AMW consortium, shares some thoughts on this significant moment. “We are very excited here at AMW because after all these years of work, the four segments belonging to Sector-5 will finally come together with the outer shell completely closed. We still have ahead of us some machining, and the final non-destructive evaluation tests to conduct, in order to conclude the fabrication phase. Then, all four segments will be positioned in the assembly frame to be welded together. In a few months from now, Sector-5 will be unveiled and this will be the biggest compensation of all our efforts. This just the start as four sectors are following closely.”

Meanwhile, works are progressing on more of the European sectors of the ITER vacuum vessel. For example, in the workshop of Belleli, Montava, Italy, technicians are also working for the AMW consortium, making good progress with Europe’s sector 3. The teams have already welded the first outer shells of segment 2. There is also news on sector 4, with start of assembly expected to kick off a few months after sector 5 goes full speed.

The start of assembly of Europe’s first sector has served as a learning curve for those to follow. Any doubts on tooling, transport and logistics will soon be answered as the teams as the reach the finish line. One thing is certain, the moment of victory is getting closer!