Ready to guide the power through sixty diamonds

Powerful microwaves will travel through these transparent and resilient diamond windows produced by Chemical Vapour Deposition (CVD). F4E has signed a contract for the production of 60 diamond discs with Diamond Materials.

Various heating systems will join forces to release their power in the ITER device so that the super-hot plasma reaches 150 million °C. Keeping these temperatures high will be a formidable task because thermal losses will occur after some time. This is why we will rely on the Electron Cyclotron and on the Upper and Equatorial Launchers to release additional microwave power to compensate for these losses. They will keep the plasma burning by targeting their beams locally to some parts, as well as heating the core of the plasma. How will the extra energy go through and stay in the hermetically-sealed vacuum vessel? Through a “transparent” yet resistant barrier made of artificial diamonds.

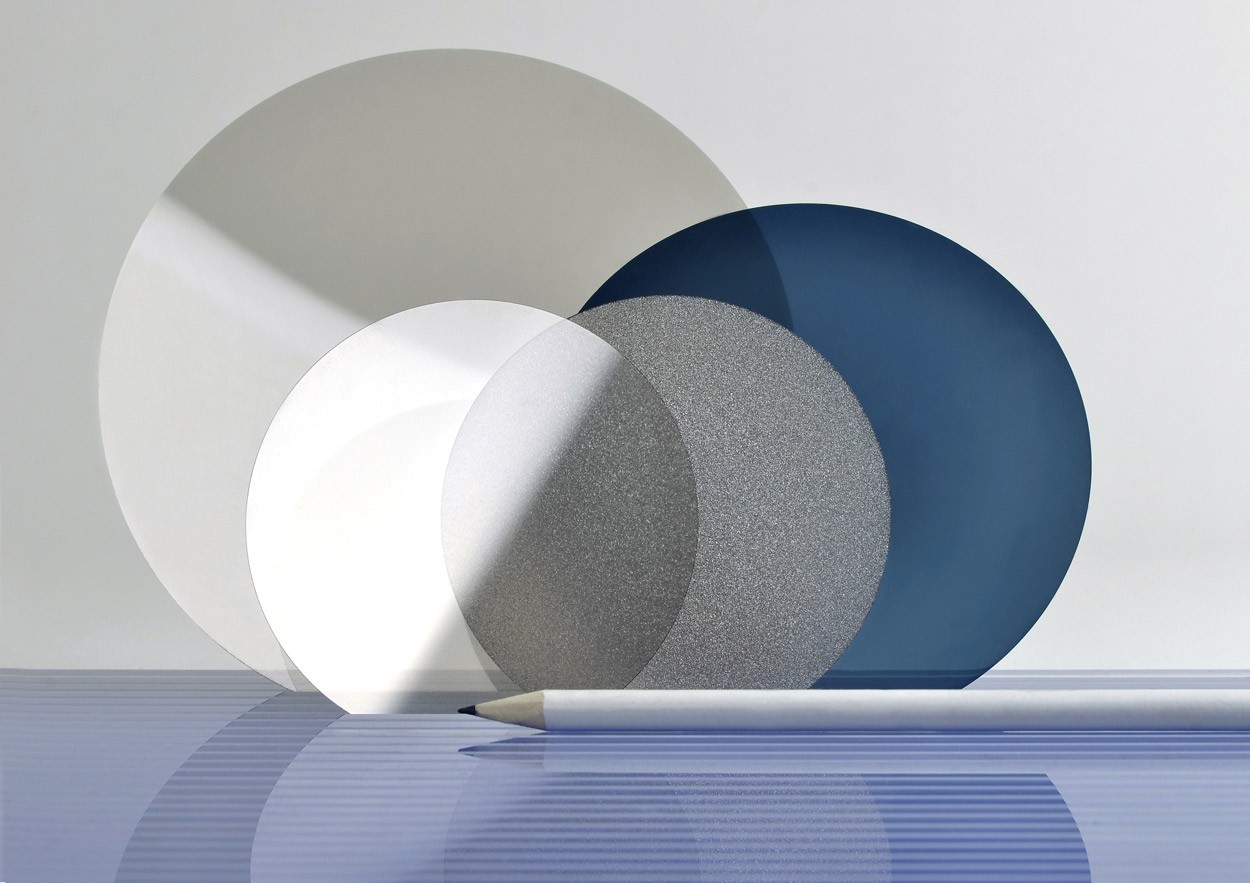

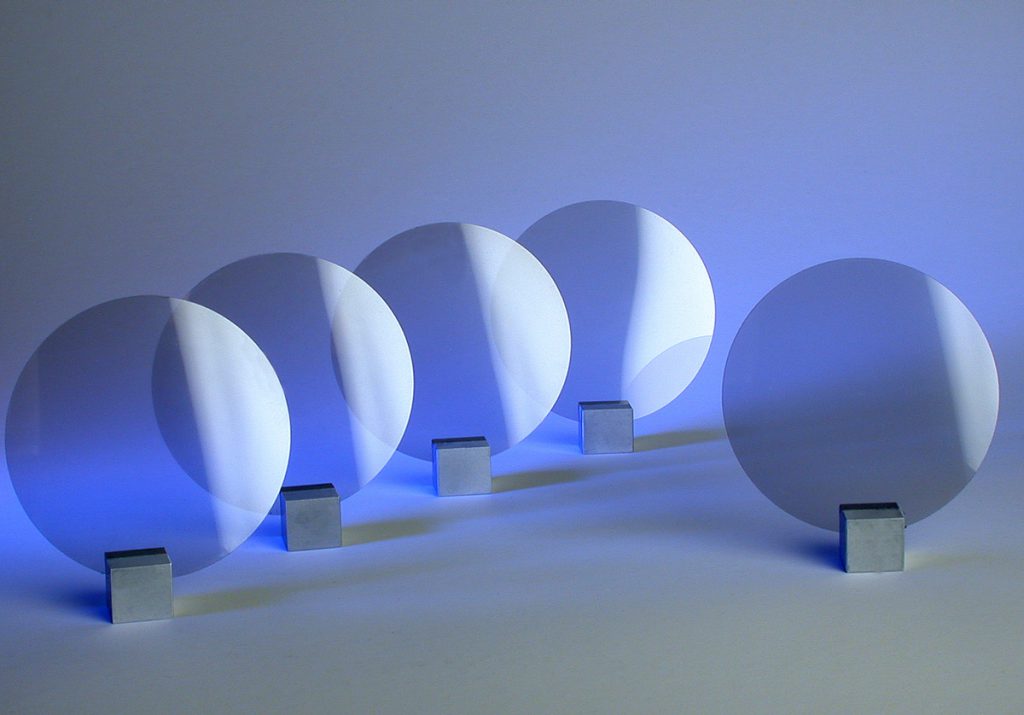

F4E has signed a contract with Diamond Materials for the production of 60 diamond discs. The German SME is a spin-off from the Fraunhofer Institute with a proven track record in the production of Chemical Vapour Deposition (CVD) diamonds. By placing layers of material a diamond slowly grows at temperatures around 800 °C over a substrate. When the diamond is fully developed it is separated from its substrate so that it can be used. The ones in ITER will be 1,1 mm thick and will have a diameter of 7 cm. They will be produced in batches of 7-10 every four months and subsequently will be tested at KIT.

Why did engineers choose this material? Windows are quite common in X-ray or laser machines used in scientific or medical facilities to offer a so-called barrier. But those widely available in the market came with certain drawbacks: first, they could not sustain the power we are dealing with in ITER; second, they absorbed part of it as it was going through. The search for the ideal diamond window began in order to meet the needs of the biggest fusion device. They would have to act as windows through which microwave beams travel and protect the systems they shield from any gases in the chamber.

A framework contract for their production was signed towards the end of last year. Since then much progress has taken place in doing the preparatory work for their production. A few weeks ago, the company completed its Manufacturing Readiness Review, a lengthy exercise which serves to confirm that all protocols, personnel, equipment, documentation and quality assurance system are in place to start the works. We spoke to Violeta Gracia, F4E Project Manager, who has been following this contract in order to get further insight. “It’s a fascinating component which needs to be small, resilient and with the right dielectric properties. In simple words this means that the power must go through quickly and dissipate swiftly. In addition, the diamond discs will need to comply with strict nuclear standards because they will provide a barrier to the vacuum vessel which will be exposed to tritium. Following the successful completion of the MRR, we are now ready to start production.”

Thanks to the high benchmark set by the ITER and the guidance offered by F4E, the company introduced a number of improvements in the documentation and quality control. This is another example where the project offered an opportunity for change. “Working for F4E is always a challenge. It takes us to the edge of what is possible and inspires us to go beyond our limits,” explains Eckhard Wörner, CEO of Diamond Materials.