Using the power of water to bring the energy of the sun

Even in the biggest fusion device the amount of free space is limited. The bulky components with their multiple parts will require an extreme level of precision to be installed and subsequently maintained. And to make matters more complicated, the majority of these tasks will be performed without being physically present in the machine.

Remote Handling systems will help us carry out such tasks from a distance deploying a vast range of technologies, including sophisticated robotics and virtual reality. In some cases, hydraulically-driven systems will need to be deployed, and given the fact that systems using oil cannot be used in case it is slips in the machine’s vacuum vessel, power systems operating with water will need to be considered. So here is an interesting contrast: the 54 divertor cassettes, which form the ITER machine’s ashtray, and receive most of the heat of the superhot plasma reaching 150 million ° C, will need to be transported with the help of a sophisticated water-hydraulics system. Fire and water will work side by side to operate the machine.

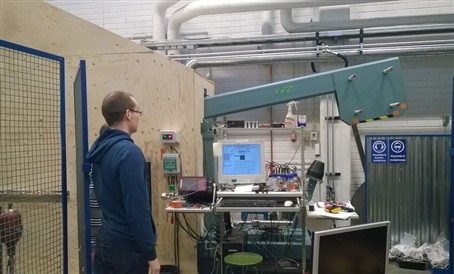

Assystem UK and the Technical University of Tampere (TUT) have tried a water-hydraulics system replicating ITER conditions by monitoring its performance during a 2000 hours endurance test. The lifting of a load weighing 1 T, using a valve operating in a confined space with high temperatures, has been successful. The performance of the prototype and wear of components have been satisfactory. The team of engineers, however, spotted an Achilles’ heel in the valves. Although, servo valves offer accurate tracking they lack robustness and wear off easily. On top of that, any particle in the water could block them easily and could cause significant problems to the operation of ITER’s Remote Handling system for the cassette divertors. For this reason, F4E has started to look for alternatives and has signed a contract with Tamlink and Hytar Ltd., part of Fluiconneto by Manuli, to explore the possibility of using digital water hydraulics to replace the servo valves. The system relies on the use of fast, small and simple on/off valves to achieve the required performance. Overall, they are more resilient and capable of operating even with a small degradation in performance.

Tamlink and TUT have invested in digital hydraulics for almost 20 years and Bosch Rexroth has licensed this technology. In fact, the digital oil valves of such kind are being used in some of Finland’s high speed trains. The next step is the commercialisation of water digital hydraulic valves and ITER will yet again prove to be a driving force in promoting more innovation.