F4E and Air Liquide get ITER’s Cryoplant ready

Exterior view of the ITER cryoplant, with the liquid nitrogen tank towering over the large facility. April 2025. ©F4E

To reproduce the Sun’s fusion reaction on Earth, ITER will create a plasma ten times hotter than the core of our star. But to bring it to life, the experiment will rely on a factory of cold. The ITER cryoplant will deliver liquid helium at 4.5K (-269 °C) to cool down the superconducting magnets and the cryopumps, as well as gas helium at 80 K (-193 °C) for the thermal shields.

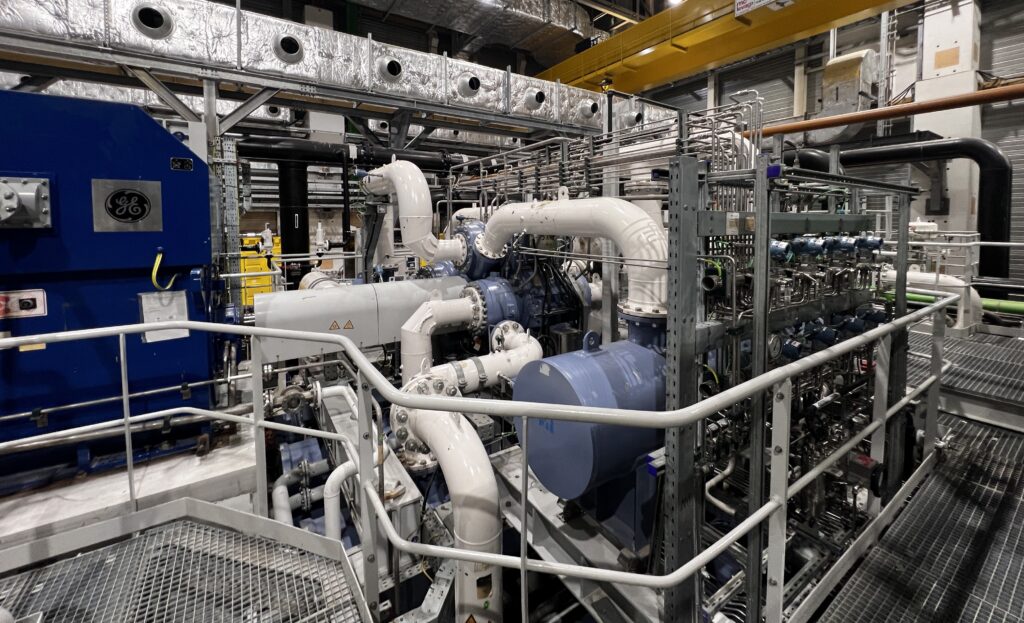

This powerful refrigerator is one of the biggest of its kind, with the surface of a football field. The cryoplant, erected by European constructors, is easy to spot thanks to 26-meter-tall storage tanks. These components will feed the intricate circuits of pipes, compressors and cold boxes, designed to produce and distribute the cryogenic fluids at the precise conditions.

Much of the cryoplant’s technologies have been shaped too by Europe’s industrial know-how. Fusion for Energy (F4E) has been collaborating since 2013 with the French firm Air Liquide to provide the Liquid Nitrogen Plant Plant—used as a pre-cooler for helium—plus a range of auxiliary systems. After delivering all the hardware to ITER, the supplier’s personnel and their subcontractors stayed onsite to install and integrate the equipment. They lifted and placed the large components, welded and tested the piping, and carried out electrical and instrumentation works. This phase has been successfully completed.

The last mechanical acceptance tests proved the different machines are leak-tight and ready to accept and handle the ultra-cold fluids. The integrated team of Air Liquide, F4E and ITER Organization started commissioning activities of major Liquid Nitrogen Plant equipment towards the end of 2024. They started by running the large nitrogen compressors and subsequently cooled down two of the nitrogen refrigerators, at the heart of the plant. In parallel, commissioning started on the helium recovery and purification systems.

Next to follow are circuits like the 80K helium loops, the cold helium storage tanks and other auxiliary systems. Altogether, Europe’s cryoplant commissioning is expected to finish by mid-2026.

“The successful completion of the nitrogen unit’s construction is a key milestone that illustrates the strong collaboration between Air Liquide Engineering & Construction and F4E, within the larger Air Liquide Group’s contribution to ITER. Thank you to all the teams mobilized for their hard work and collaborative spirit. We are proud to bring Air Liquide’s unique expertise in the field of cryogenics to this visionary project”, says Guilherme Menezes Villaca, ITER Project Director at Air Liquide Engineering & Construction.

“We have entered the most exciting phase of the project when all the previous years’ efforts are finally coming together and we can benefit from the trustful collaboration between all parties, built during those years. We keep working as one team of suppliers, ITER and F4E people to finalize commissioning of the Liquid Nitrogen Plant and prepare the whole ITER cryoplant for future operation,” explains Grigory Kouzmenko, Project Manager for F4E.

Parallel to Europe’s progress, ITER Organization is testing the production of liquid helium, the ultra-cold lifeblood of the massive fusion reactor.

Watch this animation by Air Liquide to see how the cryoplant will work.