F4E delivers all magnetics diagnostic equipment for ITER

F4E and ITER Organization colleagues during the site acceptance tests of one of the batches of sensors. ©F4E

In ITER, powerful magnets will confine and shape the super-hot plasma. During experiments, operators will need to track the magnetic fields continuously. ‘Reading’ them will help to understand and control the plasma’s behaviour in real time. To get this information, ITER will use the magnetics diagnostic, provided by Europe for the most part. The system relies on a vast range of sensor coils placed around the machine to capture changes in the magnetic fields. Their signals are then transmitted through cables and processed by a set of electronics and data-analysis software.

Fusion for Energy (F4E) has now delivered all its equipment for the entire system, including sensors, electronics and software. The diamagnetic coils were the last of many batches arriving onsite in the last nine years. In total, F4E’s suppliers produced close to 900 sensors for twelve different sub-systems. Most of them are pick-up coils, designed to measure local magnetic fields. They will be mounted on the inner and outer walls of the Vacuum Vessel as well as on the Divertor Cassettes.

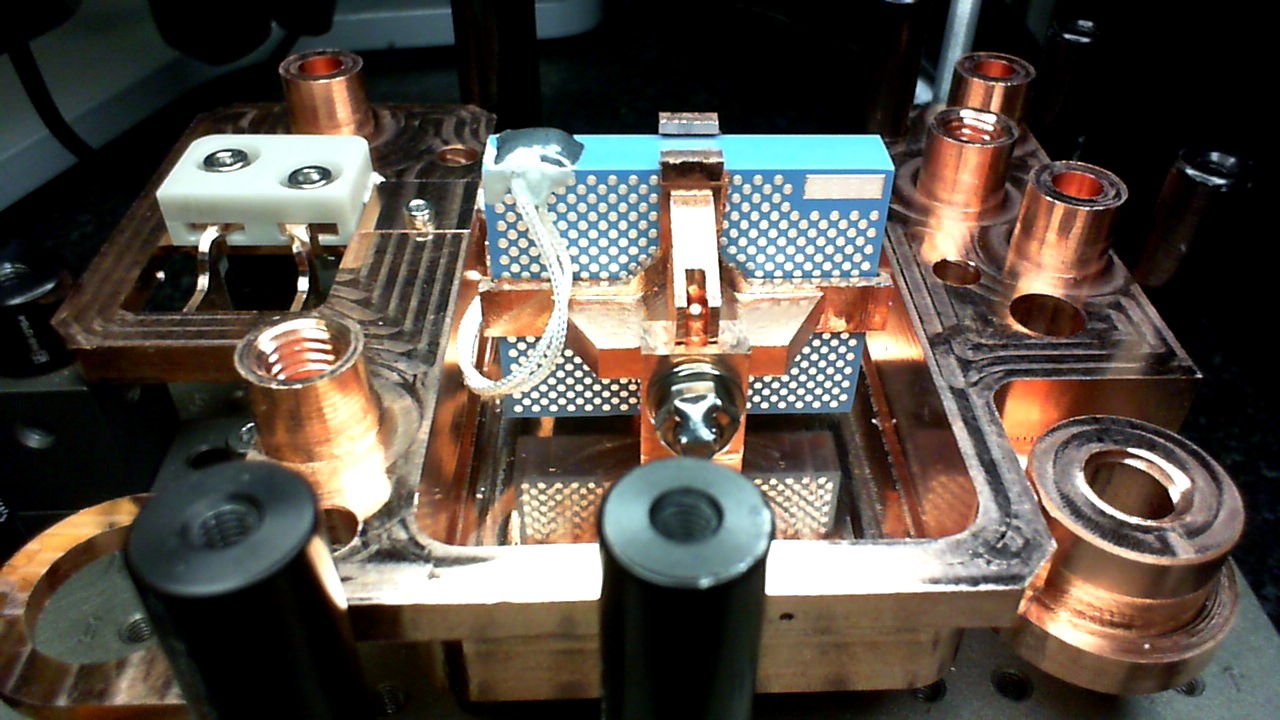

These pick-up coils are engineered to withstand ITER’s extreme thermal, radiation and electromagnetic conditions while providing accurate measurements. In essence, they consist of a conductor precisely shaped (either wound or printed) and integrated onto a mechanical platform. Many of the coils fit in the palm of a hand. Manufacturing them in such compact space requires advanced materials and techniques, tailored to the location and target of each sub-system.

The outliers in the project were the Continuous External Rogowski (CER) coils, much larger than the rest. The CER will do a 40-meter loop within the Toroidal Field coil cases. They will operate at ultra-cool temperatures and measure the total plasma current.

Given the breadth of components, F4E partitioned the work in various contracts and managed a chain of skilled European suppliers. These included VIA Electronic, Thermocoax, UKAEA, Sgenia, Elytt Energy and Axon Cable. Their tasks ranged from manufacturing the different sensors, platforms and supports, to integration and testing. The production required highly specialised techniques, like low temperature cofiring, high-precision machining of fragile materials or winding and brazing very fine cables. Once ready, each pick-up coil was calibrated to determine their exact sensitivity and orientation.

Throughout the process, F4E was the nexus between manufacturers and coordinated with ITER Organization, the designer and final user of the sensors. Paz Casas Lino, F4E Project Manager, describes it as a fruitful learning curve: “The first unit of each type required the most work, as we had to adjust aspects of the design and come up with manufacturing solutions. But the proactive attitude and excellent collaboration between F4E, ITER Organization and the suppliers paved the way for a successful series production.”

In fact, the know-how gained in this project is helping expand the suppliers’ market reach. For example, the SME VIA Electronic is tapping into new business opportunities in other energy projects, thanks to the support of F4E’s Technology Transfer Programme (read the recent success story).

Meanwhile, the sensors onsite are being gradually installed onto their components. The ITER assembly teams already placed the outer vessel coils and are currently preparing for the installation of the inner vessel ones. In addition, integration activities are progressing onsite for Europe’s electronics and software, delivered in the last years.