Design of ITER diagnostic system nearly completed

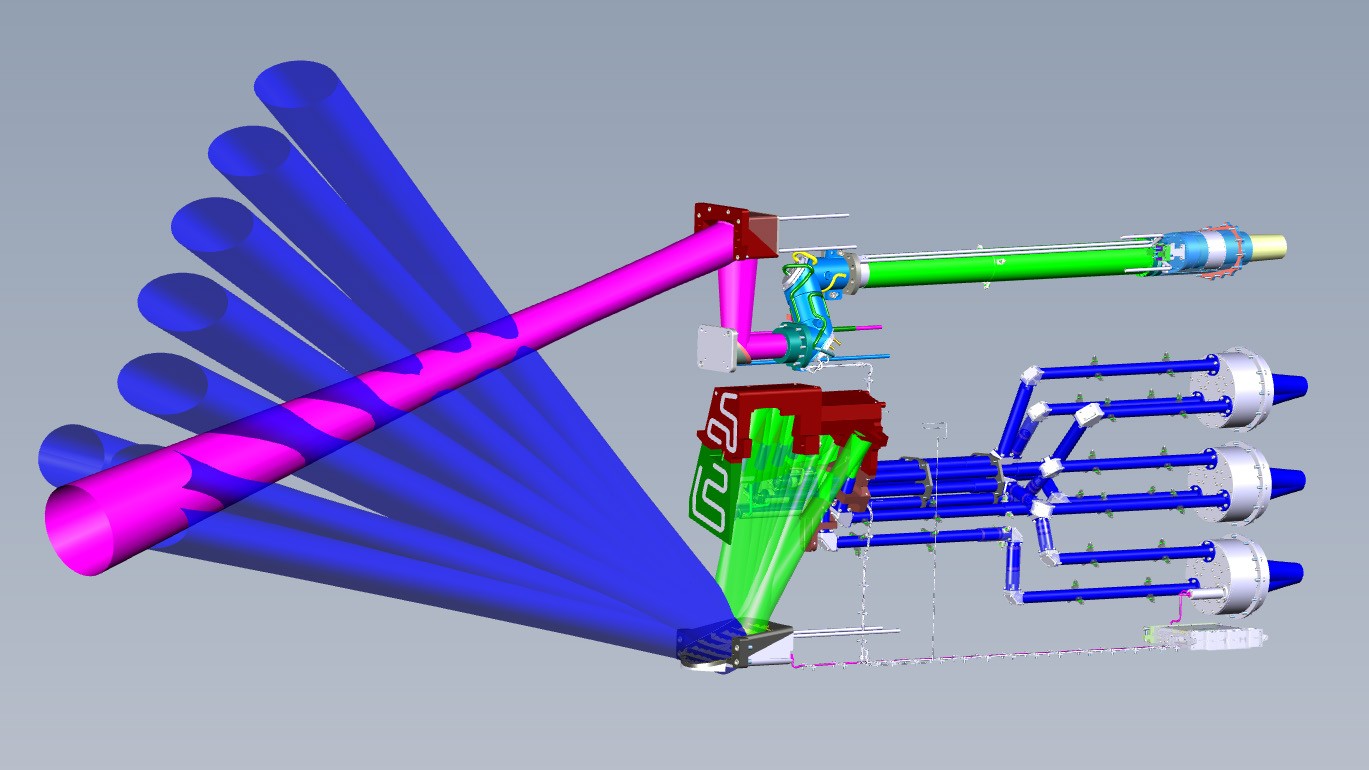

Side view illustration of the Collective Thomson Scattering design. The high power probe beam is illustrated in purple, whereas the information gathered by the receivers is shown in dark blue. © DTU

Inside the ITER Vacuum Vessel, dozens of diagnostic systems will be the eyes and ears of the experts, monitoring the conditions of the experiment. The Collective Thomson Scattering system (CTS) will be one of them, devoted to measure the amount of alpha particles (helium nuclei) and other fast ions in the plasma.

Alpha particles are the natural result of fusion reactions, as they are obtained from deuterium and tritium nuclei, the “fuel” gases of the plasma. Fast ions may also be produced by the plasma heating systems, and must be well confined to keep the experiment at high temperature and avoid disturbances.

The CTS will measure these particles by launching a powerful beam of radiation into the plasma. The radiation scattered by the plasma is then collected and measured, which gives information about the fast ions. The system will consist of a source of microwaves that will work at 1 MW of power –almost like 1 000 microwave ovens operating at full power–, transmission lines, front-end components such as mirrors to deflect the radiation to be launched or collected, and data acquisition and processing electronics. F4E will provide the front-end CTS system, while ITER Organization is in charge of designing the rest of the parts.

“This is a challenging system. For example, the line injecting the power is made of mirrors and waveguides, which are used to direct the radiation. We needed to design a special structure to cope with 1 MW, which is a lot of power, in order to avoid electric discharges during operation,” explains Laura Sánchez, F4E Project Manager.

In November 2019, ITER Organization signed a Procurement Agreement with F4E to develop the system, which had already been sketched. Shortly afterwards, in March 2020, the preliminary design review of this system was completed. Since then, experts from F4E and several suppliers have been concentrating on more specific design details to ensure a functional device. DTU and IST have focused on system performance, remote handling and neutronics analyses, IDOM has performed thermal and structural analyses, NATEC has dealt with the electromagnetic features of the design, and AVS has given support to the mechanical design and worked on assembly procedures. With only minor tasks pending prior to fabrication, a call for tenders has already been launched to look for possible manufacturers.