Europe acquires new tool for ITER Vacuum Vessel inspections

A part of ITER Vacuum Vessel sector 5, holed like a Gruyère cheese, with dozens of housings. Mangiarotti, Italy, November 2021. © F4E

The interior of the ITER Vacuum Vessel will be covered by 440 blanket modules aimed at protecting the inner walls and components of the machine. These modules will be attached to a total of 1760 housings, around 200 per vacuum vessel sector. Experts use the housing axes as reference to define the positions of other parts of the vacuum vessel.

Consequently, determining the real dimensions of the housings is crucial. These components have a smooth part and a thread with grooves that need to be carefully examined. To address this task, F4E has procured an inspection tool that performs these measurements accurately and quickly. Experts need roughly one hour to perform all the necessary measurements manually in each housing. With the help of this novel tool, only five minutes are required!

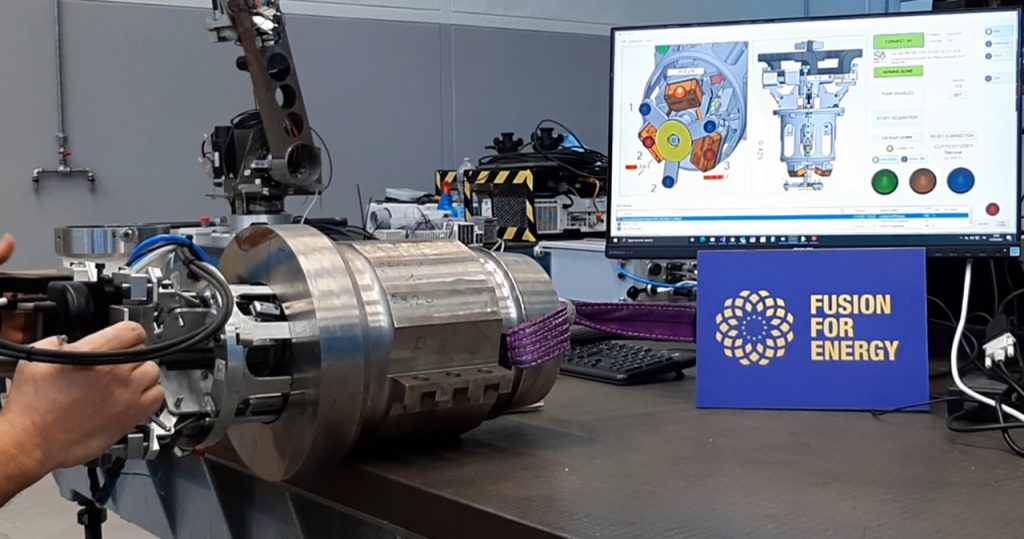

AXIST has designed, fabricated and tested the tool based on specifications provided by the F4E Metrology team. It consists of a cylinder-shaped steel structure containing a platform with three lasers to scan the interior of the housing. As there are housings of two sizes (130 mm and 150 mm of diameter), there are two versions of the tool, one for each size. Experts perform the measurements by introducing the tool inside the housing, and either with the help of a hand crank or an electric engine, the platform containing the lasers rotates and moves lengthwise inside the housing, scanning its interior. A software is also included to process the obtained data, which have an uncertainty of 0.01 mm.

Alessandro Lo Bue, F4E Metrology expert, tells us more about the tool. “We have already used it in the Poloidal Segment 3 of ITER Vacuum Vessel sector 4, in Walter Tosto, with good results. For sure, the tool will be useful in the Factory Acceptance tests and Site Acceptance tests of the five European vacuum vessel sectors.”