Europe and Japan test materials for future fusion reactors

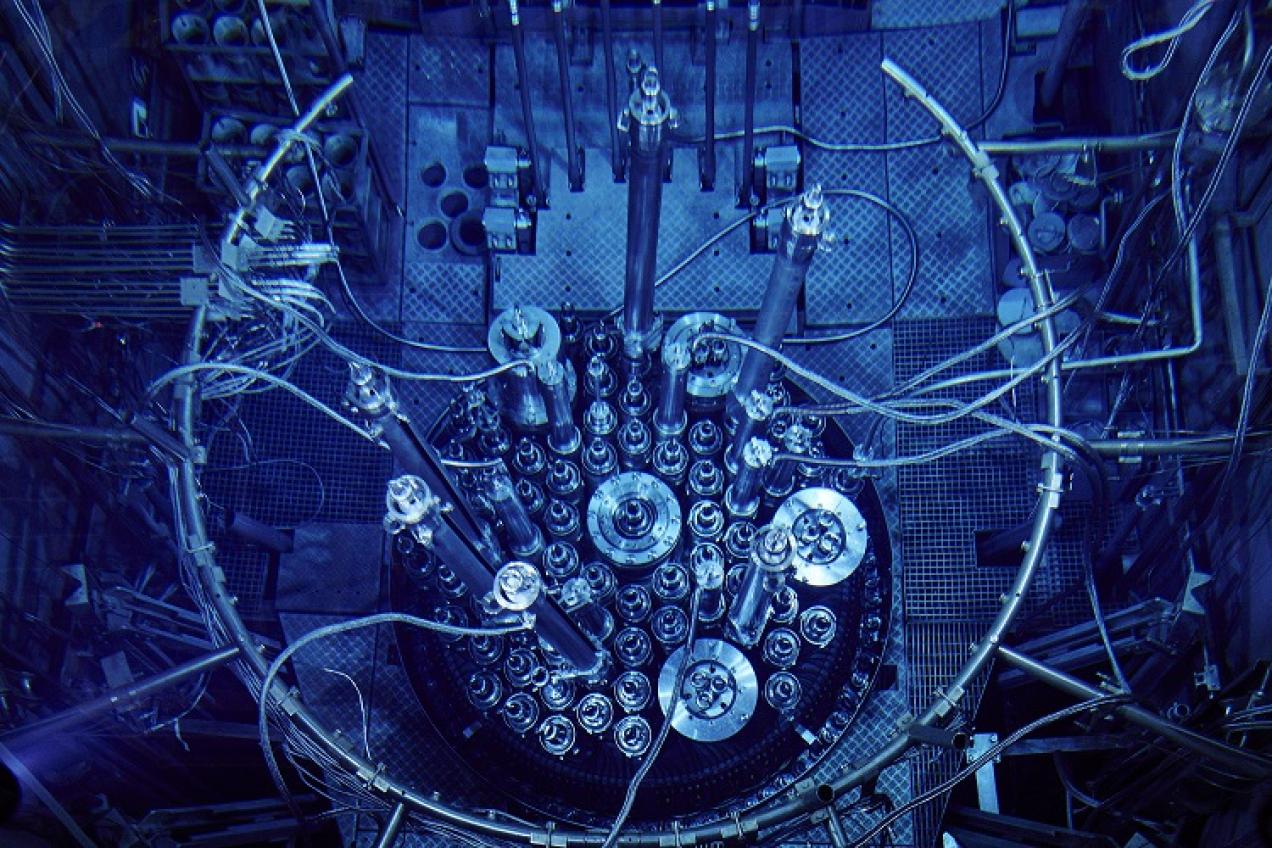

The Belgian Reactor 2 (BR2) at SCK CEN, placed in a water basin, can irradiate materials with high neutron flux ©SCK CEN

Large-scale projects like ITER are pushing the boundaries of fusion as a viable energy source. Yet, ITER’s groundbreaking nature remains largely experimental. Its successor, DEMO (Demonstration power plant), is considered the ultimate stepping stone towards commercial fusion reactors. The plans for this next-generation device aim to build on the know-how from ITER and go beyond, with longer operations and a high output of net electricity.

To this end, DEMO’s design will feature a closed fuel cycle, thanks to the regeneration of tritium. It is an essential process for the self-sufficiency of a reactor, harnessed through the so-called breeding blanket inside of DEMO. Experts know the principle well: when the neutrons released in the fusion reaction interact with lithium in the blanket, it generates tritium, which can then be processed and injected back into the vessel to fuel the reaction. However, engineering the blanket has been a long-standing challenge in fusion research. One of the critical questions is: which materials can withstand the extreme conditions inside the reactor while efficiently breeding tritium?

Europe and Japan set out to find answers together through the International Fusion Energy Research Centre (IFERC), within the Broader Approach agreement. Fusion for Energy (F4E) and the National Institutes for Quantum Science and Technology (QST) collaborate in R&D activities on breeding materials for DEMO. EUROfusion is now the main EU contributor, with several laboratories carrying out a great share of the technical work. This joint project complements F4E’s Test Blanket Module programme, a unique opportunity for scientists to test concepts for tritium regeneration in ITER.

During the first phase (2007-2020), Europe and Japan developed their respective alloys for the neutron multiplier, the intermediate layer that generates additional neutrons, and the lithium-based breeder. “Besides their function in the tritium cycle, the materials must meet very stringent conditions to guarantee they are fit for DEMO, from low activation to availability and cost. The choices are based on an extensive analysis, but we need even more information to fully characterise and qualify the materials”, explains Raúl Guillén, Procurement Agreement Manager for IFERC at F4E.

The alloys were therefore poised for some experimentation to get a fuller diagnosis of their performance. As part of the second phase, the IFERC teams partnered with the Belgian research centre SCK CEN to use the material testing reactor BR2. The post-irradiation experiments, running for a year from 2024, have two steps. First, BR2 will expose the samples to high-energy neutrons, much like those a blanket must withstand inside a fusion device. Then, the specimens will move to the Karlsruhe Institute of Technology (KIT), in Germany, where experts can examine the effects of the irradiation on their mechanical properties.

Whilst this happens, a parallel round of tests will start by the end of the year at the Institute of Nuclear Physics (INP) in Kazakhstan. The WWR-K reactor will expose the European and Japanese breeders to neutrons mimicking fusion conditions. This way, researchers will be able assess the materials’ capability to produce and release tritium – their crucial task within future reactors.

The results from these activities will feed into common databases and engineering handbooks for the construction of DEMO. “Thanks to the diligent preparation by the European and Japanese teams, along with the collaboration of SCK CEN, KIT and INP, we will make best use of the experiments. The knowledge we gain on breeding materials will be shared with the fusion community,” claims Guillén.

“Material characterisation lies at the very foundation of the stepwise nuclear qualification approach that Europe is developing for the breeding blanket,” asserts Salvatore D’Amico, technical responsible officer at EUROfusion. “The current experiments are laying the groundwork for upcoming irradiation campaigns in DONES”, he adds.