F4E signs contracts for the pre-qualification for the Divertor Inner Vertical Target

With the objective of fostering competition, F4E has signed framework contracts for the manufacturing of divertor inner vertical target (IVT) prototypes with the two French consortiums ALCEN-ATMOSTAT and CNIM-TPI, as well as the German company Research Instruments. These three contractors join the already existing approved contractor Ansaldo Nucleare in their bid to pre-qualify as F4E suppliers.

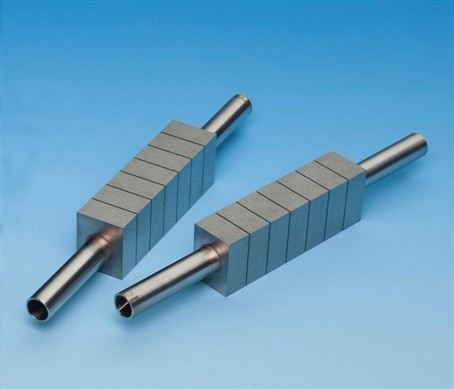

The multiple framework contract involves two stages: The first (pre-qualification) stage entails each of the contractors validating the fabrication technologies they have proposed by manufacturing and testing small-scale mock-ups of the IVT. Contractors who submit small scale mock-ups that pass F4E’s acceptance tests can then re-compete for the second (qualification) stage of the framework contract, namely the manufacturing of full-scale IVT prototypes.

With different companies contracted, F4E ensures that competition is healthy and fair. An additional advantage is that different technologies will be developed that mitigates technical risks. “We are working to find the right compromise – we need enough different contractor companies for the pre-qualification stage in order to have enough competition when we then get to the qualification stage”, explains Patrick Lorenzetto, Project Team Manager of F4E’s In Vessel Team. “All these companies will be able to develop their skills and technologies while manufacturing the small scale mock-ups which will make them valid possible contenders for winning the second stage of the contract for the full-scale version. That we use resources at this first stage will help us mitigate risks and additional costs later on during the series production stage, when the actual components for the ITER machine will be manufactured”, he adds.

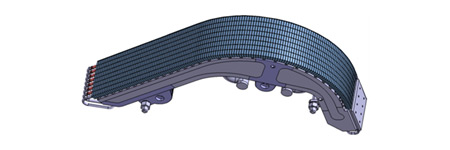

Located at the very bottom of the vacuum vessel, the ITER divertor is made up of 54 remotely-removable cassette bodies, each holding three plasma-facing components (namely, the inner and outer vertical targets and the dome). The technical design will enable the targets, in their lower part, to intercept the magnetic field lines, and therefore divert (thus the name ‘divertor’) the high particle heat flux load coming from the plasma. F4E is responsible for providing the inner vertical target, the cassette bodies and the mounting of all the plasma-facing components, together with the required diagnostics and instrumentation, on the cassette body. The Japanese and Russian Domestic Agencies are responsible for providing the outer vertical target and the dome respectively.

With the framework contract signatures now in place, the companies will have approximately 18 months for the manufacturing of the IVT small-scale mock-ups. The second stage of the competition, the manufacturing of the full scale prototypes, is scheduled to be launched by the end of 2016. This latter stage should last about two and a half years after which the Call for tender for the series production will be launched.