How will we extract the particles from ITER Cryopumps?

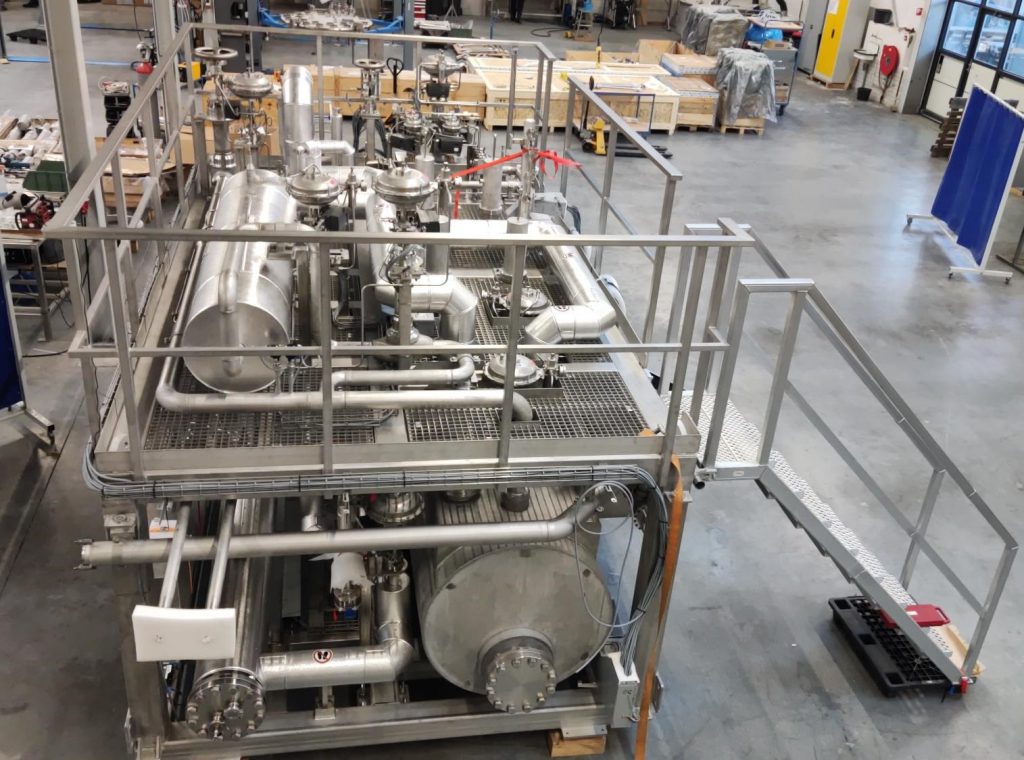

The warm regeneration box in the Cryoworld premises, some weeks before delivery to ITER Organization. Netherlands, November 2021. © F4E

ITER will have several cryopumps to ensure the proper vacuum conditions in the experiment. After some time, however, the equipment will get saturated of gas particles and will need to release them to continue pumping correctly. Europe has just delivered to ITER Organization the warm regeneration box, a piece of equipment that will help to perform this task.

The warm regeneration box is a 15-tonne machine measuring approximately 5 m long, 2.5 m wide and 2 m tall. It consists of a circuit of pipes with valves, electrical heaters and heat exchangers that enable to rise up the temperature of the cryopumps. When they accumulate too many gas particles, experts will perform an operation to remove them called regeneration. Depending on the type and amount of particles to be extracted, regeneration may be conducted with helium at 100 K, 300 K or 500 K (-173 °C, 27 °C or 227 °C). In this way, gas particles trapped in the usually super-cold cryopump surfaces will detach from them.

Research Instruments (RI) has been the main contractor in charge of this piece of equipment, since the signature of the contract in 2018. They had to develop the final design of the equipment and follow its production and delivery. The final design review meeting, held in March 2020, was the last in-person gathering before the lockdown due to the COVID-19 pandemic. Thus, all the manufacturing and assembly processes have occurred during the pandemic restrictions. The cost of all the activities related to this component was roughly 1.2 M EUR.

“It was quite a challenge to complete the design and the manufacturing of this unique cryogenic equipment. We accomplished this milestone with the support of our partners Cryoworld, VELAN and Kraftanlagen Heidelberg, and thanks to the good collaboration with the F4E and ITER Organization experts. Now, we are looking forward to continuing this excellent partnership on the production of the large cryogenic valve boxes needed to supply the ITER Torus and Cryostat Cryopumps with liquid helium,” explains Dr Michael Pekeler, RI Director.

The warm regeneration box will be installed in the Tokamak complex, once the site acceptance test is completed. “As with any component designed for the ITER project, there were a lot of challenges to sort out for the warm regeneration box. Additionally, we had to learn how to work in the context of a pandemic with a huge number of subcontractors and suppliers. It is thanks to the transparent and good collaboration built between RI, ITER Organization and F4E that we have been able to deliver this equipment,” concludes Josep Benet, F4E Project Manager and Technical Responsible Officer.