Remote Handling design for ITER Diagnostics port plugs successfully validated

“These successful tests have shown conclusively that our Diagnostic Shielding Module is well-optimised for remote handling maintenance of port-based diagnostics, a key milestone in our design activities”, observes Fabien Seyvet, F4E’s Project Manager for Diagnostics port integration activities, after witnessing tests on a full-size mock-up at the RACE centre for robotics and autonomous systems in Culham, UK.

In order to get a good view of the ITER plasma, many of ITERs diagnostics must sit right at its edge: in one of the most challenging environments on ITER. Fortunately, Diagnostic Shielding Modules, or DSMs, are there to provide them a safe home. These steel structures, which are mounted in many of ITERs port plugs and weigh up to 3 tonnes each, support and protect the delicate Diagnostic components whilst shielding from ITERs neutrons. F4E will supply nine such modules; installed in the five Diagnostics port plugs (of 18 in total on ITER) that F4E is providing.

Because the DSMs, and the diagnostics themselves, cannot be handled by humans, maintenance and repair must the done by Remote Handling; where sophisticated manipulators, remotely controlled by operators, must replace a technician’s trained hand (think of trying to change a car tyre wearing boxing gloves, and you can visualise the difficulties). Designing a DSM for compatibility with such a difficult task has been a driving requirement behind F4E’s Diagnostics port integration activities but the only way to know if the hard work had paid off, was to test in a realistic environment and with actual remote handling tools.

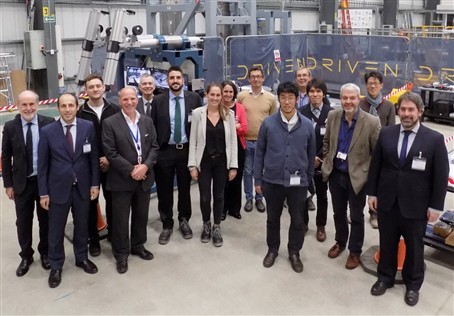

Testing included critical remote handling operations for the DSM, including splitting the ‘clam-shell’ design into two halves, and installation/removal of mock-ups for components of the ITER Edge Thomson Scattering (ETS) diagnostics system. The tests were led by experts from RACE, part of the UK Atomic Energy Authority’s (UKAEA) facilities at Culham, UK (also site of the world’s largest tokamak, JET). Observing the tests were members of F4E’s Diagnostics Project Team, representatives of ITER IO as well as of IDOM, F4E’s Spanish partner company dealing with the design and integration of the Diagnostic port plugs under F4E’s responsibility. Also keeping a close eye on the events were members of the Japanese Domestic Agency for ITER, who designed the ETS system.

“We are happy that the Remote Handling compatibility of our Diagnostics DSM design has been proven. We appreciate the collaboration we have had with the Japanese Domestic Agency, our partner company IDOM ADA and ITER IO – together we have paved the way for this favourable result. The experience and qualified staff of RACE have also enabled us to achieve these good results and given us the confidence that our designs will succeed once manufactured”, says Glenn Counsell, F4E’s Diagnostics Project Team Leader.

With the confirmation of Remote Handling compatibility now received, IDOM ADA will concentrate on developing further the port designs, in view of the future manufacturing and assembly phases.