Diamonds for fireballs

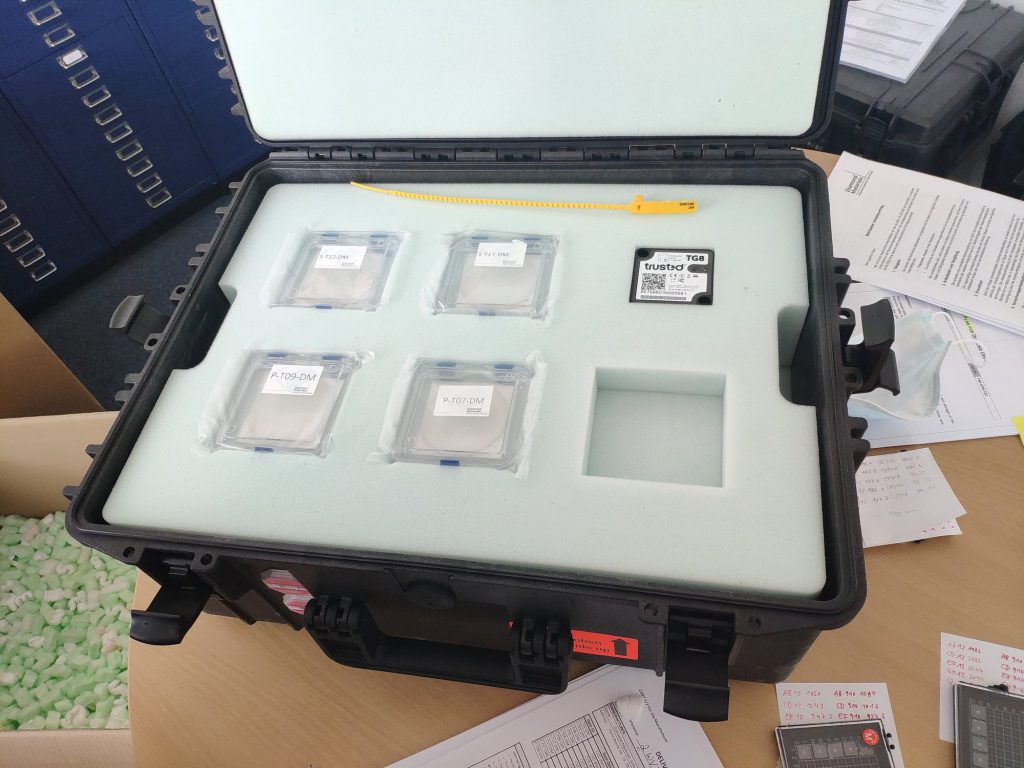

Checking the documentation of diamond discs, produced by Diamond Materials for Fusion for Energy, 2023. ©F4E

Several heating systems will unleash extra microwave power to heat the ITER plasma, which is expected to reach 150 million °C. By targeting different parts of the hot gas, they will compensate for any drops in the temperature and keep it steady. How will these “fireballs” get through the hermitically sealed vacuum vessel? The answer lies in small transparent resistant windows that will allow them to travel in the heart of the device. Diamonds will act as the gates that will allow the super-hot power of the Electron Cyclotron and the Upper and Equatorial Launchers to enter the tokamak.

Thanks to a contract signed between F4E and Diamond Materials, Europe commissioned the production of 60 diamond discs. Step by step the production has been advancing. Earlier this year, however, we hit an important milestone with the completion of all 60 diamond discs (56 needed for ITER plus 4 spare). This was important both for F4E and for the German SME, stemming from the Fraunhofer Institute, which boasts a proven track record in the production of Chemical Vapour Deposition (CVD) diamonds.

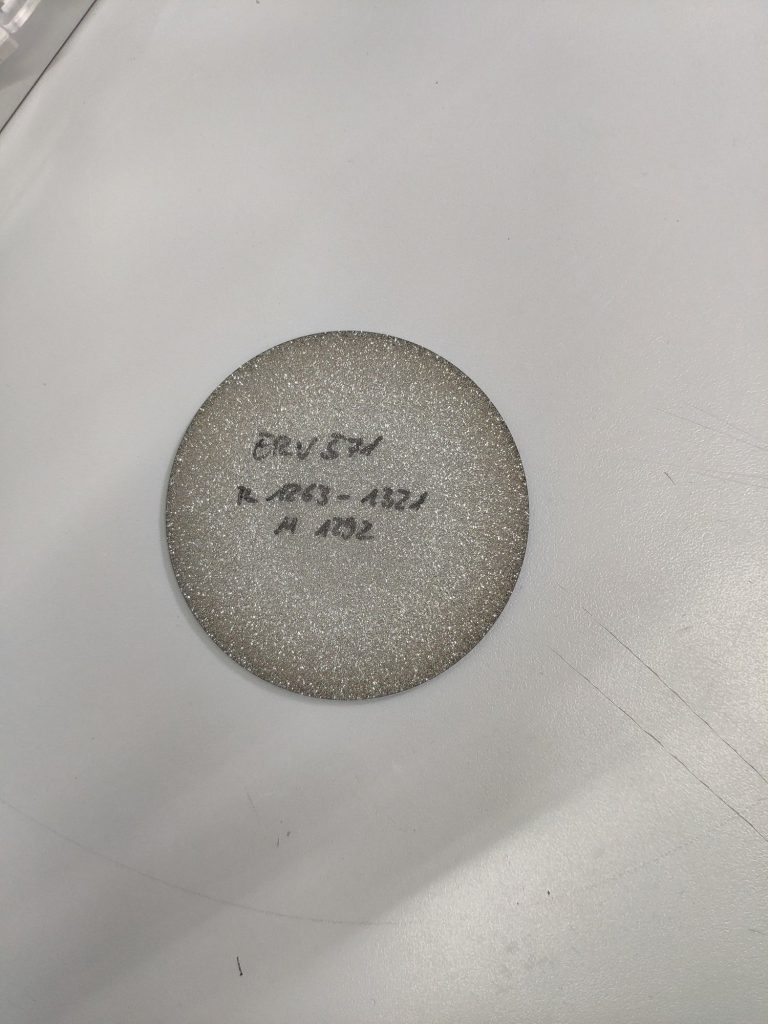

How are these diamond discs manufactured? Roughly, it takes two months to develop a diamond in 40 small furnaces of the factory. When the diamond is formed, it gets separated from its substrate. Next, it is cut to comply with the ITER specifications (1,1mm thick with a 7cm diameter). Later, the surface of the diamond disc gets polished to be optically tested at the Karlsruhe Institute of Technology (KIT). So far, 15 of these diamonds have been tested successfully, as each test lasts roughly two months.

What happens next? The diamond disc will be inserted in the so-called Diamond Window Unit (DWU), where it will be brazed. In ITER, these units are classified as parts of the first wall of confinement, because they put a barrier between the components inside the vessel and those outside. Through a contract signed between F4E, IDOM, and Alsymex, works for the design of the DWU have started. Their manufacturing is expected to be completed by the end of 2026.

Pablo Estebanez, following the contract on behalf of F4E, explains the significance of this milestone. “We are pleased to have successfully completed the production of all diamond discs, and we are moving full speed with their tests. I would like to thank Diamond Materials for the good collaboration, highlighting with their contribution that European SMEs can play an important role in ITER, because they have expertise and a level of agility. I would also like to thank KIT for helpings more ahead at the next phase of the project, by conducting tests.”

For Eckhard Wörner, CEO Diamond Materials GmbH & Co. KG, this achievement is equally important. “We are happy and proud to have completed the production of 60 diamond discs that will be used as ITER torus windows. During production we had to deal with expected and unexpected challenges, but in the end everything went well and we were able to stay on schedule. My impression is that we are ahead of all the other components of the upper launcher.”