Europe delivers equipment for ITER Vacuum Vessel diagnostics

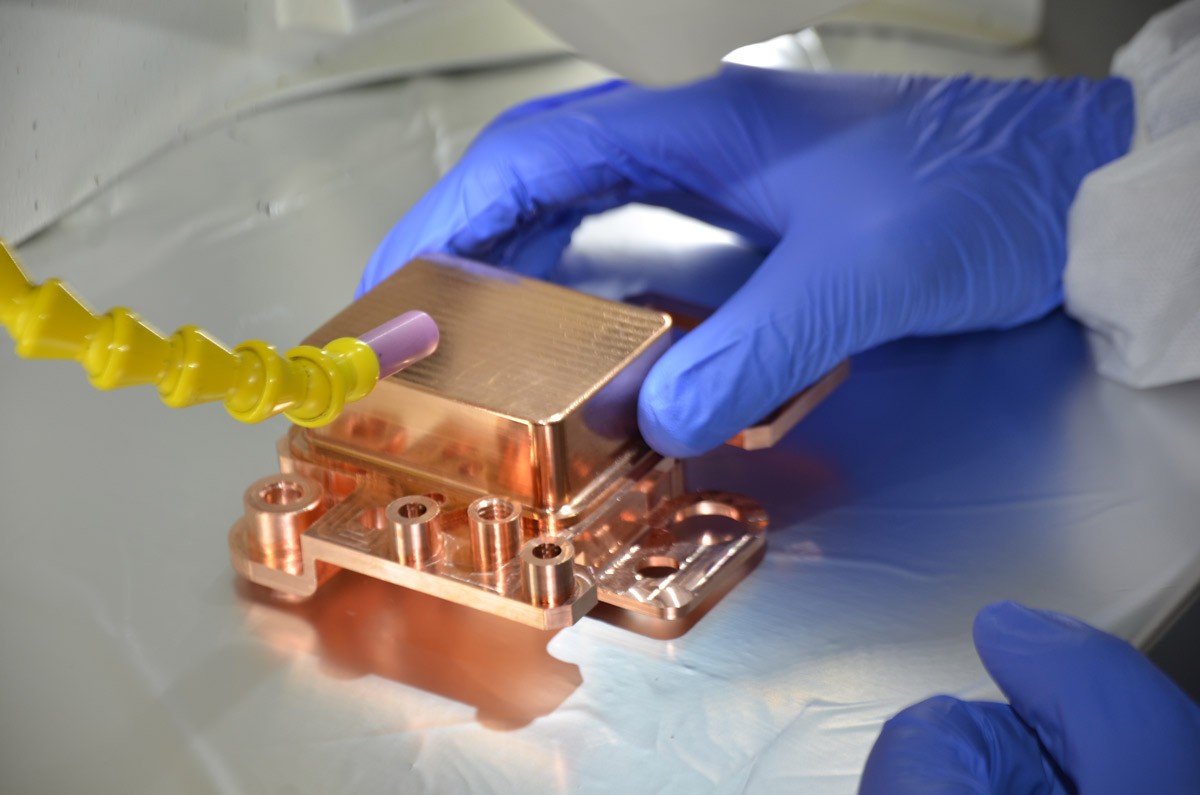

First of series of a mechanical platform for ITER the diagnostics of Inner-Vessel coils produced by Sgenia through a contract signed with F4E. Their manufacturing includes the processing of nickel alloys, ceramic materials together with other copper alloys and advanced joining techniques.

To measure the plasma behaviour of the ITER device, its energy, and instabilities approximately 450 sensors will be installed in the vacuum vessel to help scientists receive this information. Our engineers are confronted with a number of technical challenges due to the fact that these components will need to function in an environment of extremely high temperatures, vacuum, radiation and little maintenance. F4E is responsible for the production of the sensors and the platforms in which they will be housed.

Through a contract signed with Sgenia in 2017, the company has been entrusted with the manufacturing of the platforms, whose main role is to offer mechanical support, shielding, conduct heat and ensure electrical connectivity for the coils. Metallic alloys and ceramics will be used for their fabrication. Sgenia will also take care of the assembly integration, welding operations, fixations and the electrical connections for five of the six types of assemblies to be used. In August, the first batch consisting of 2 500 small assemblies was delivered to the ITER site, Cadarache. The remaining three batches, amounting to 450 larger assemblies, will also be handed over to ITER Organization to proceed with their installation on-site. All works from this contract are expected to be completed by 2022.

“Our good collaboration and the commitment of all parties to make up for any time lost due to the covid pandemic have been instrumental in meeting the objectives of this year’s project plan. The first batch has been successfully delivered and the second batch will arrive next spring,” explains Angela Hernandez-Sanchez following this contract on behalf of F4E.

Jesus Lama, Sgenia Project Manager, offers his point of view on the progress of the works. “The manufacturing of the mechanical platforms for the diagnostics of the magnetic Inner-Vessel coils combines high tech material and advanced manufacturing techniques. The production route has been carefully selected to comply with a medium size production and the strict specifications of the project.”