Europe’s In-Vessel Viewing systems tested on ITER prototype

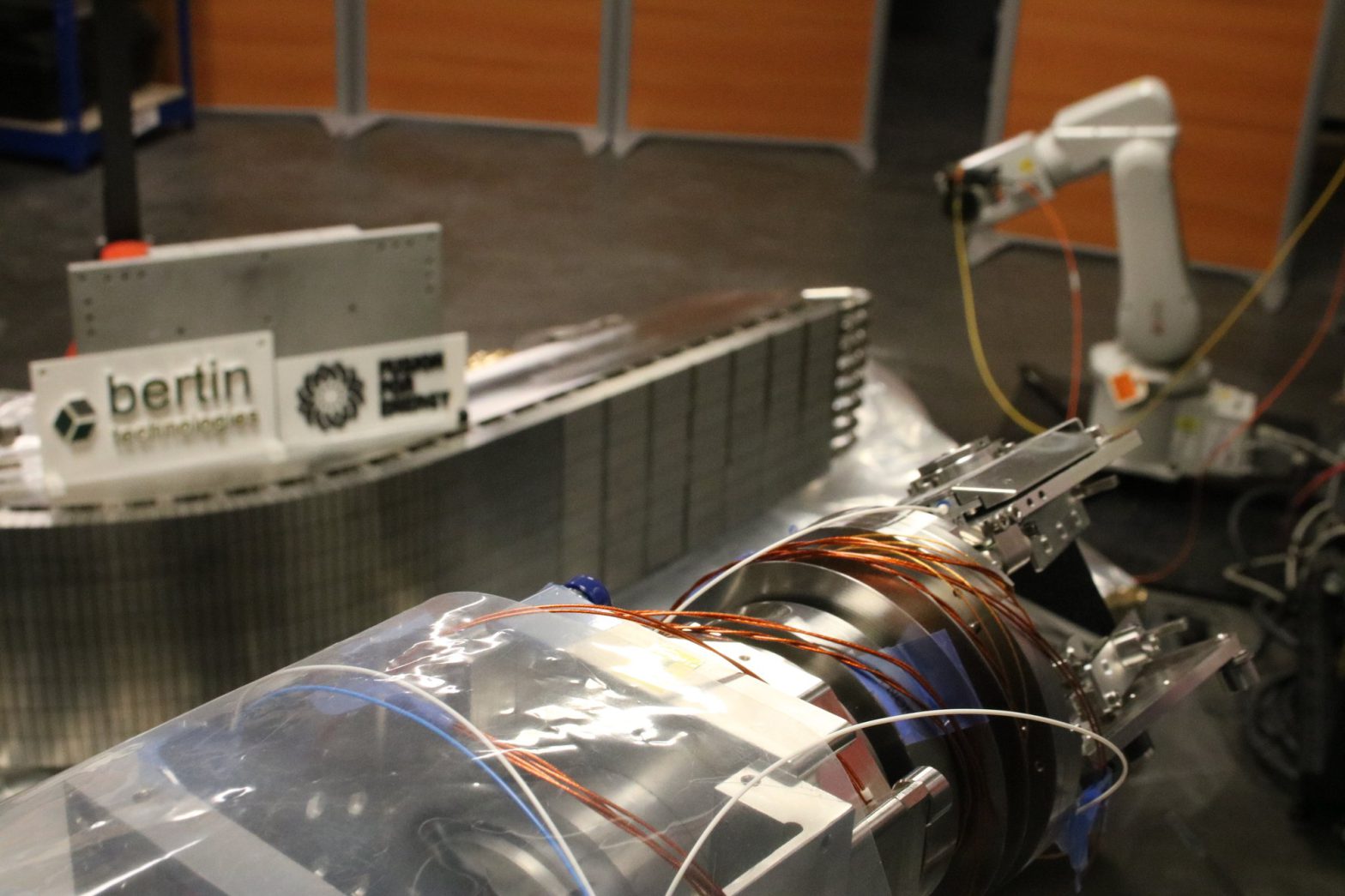

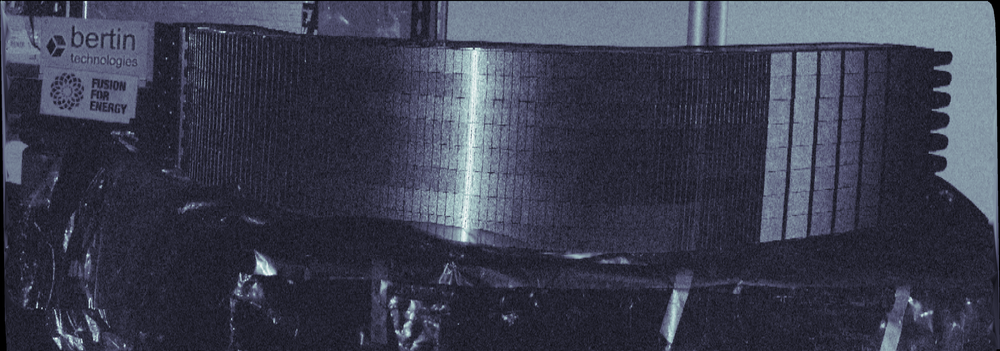

The IVT prototype, manufactured by Research Instruments, undergoing inspection by the In-Viewing System probe prototype in the workshop of Bertin Technologies, France. May 2023 ©F4E

The inspection of components located in the heart of the ITER reactor will be one the most challenging tasks. The size of the wall that will contain the burning plasma, the geometry of the in-vessel components that will be exposed to the heat, and the fact that all interventions will need to be conducted remotely, raise the level of complexity substantially. Teams of engineers across Europe are working with F4E to deliver the In-Vessel Viewing System (IVVS) that will allow technicians to scan thoroughly the surfaces and to detect any damage or erosion. How? An optical probe will direct laser beams on to the In-Vessel components and use the reflected light to check their state.

Following the approval of the IVVS Preliminary Design Review in 2021, F4E signed a contract with Bertin Technologies to develop a full-scale probe prototype of the measurement system. During this process, engineers from F4E, ITER Organization, and companies, collaborated to assess existing knowhow, identify strengths, risks, and finetune specifications. There is no better way of doing this other than performing tests on an existing piece of equipment which has been purposedly damaged. This is exactly what F4E did by using the probe on an Inner-Vertical Target (IVT), a component that will offer protection to others from super-hot plasma particles. The IVT, manufactured by Research Instruments, was transported from ITER Organization to the workshop of Bertin Technologies.

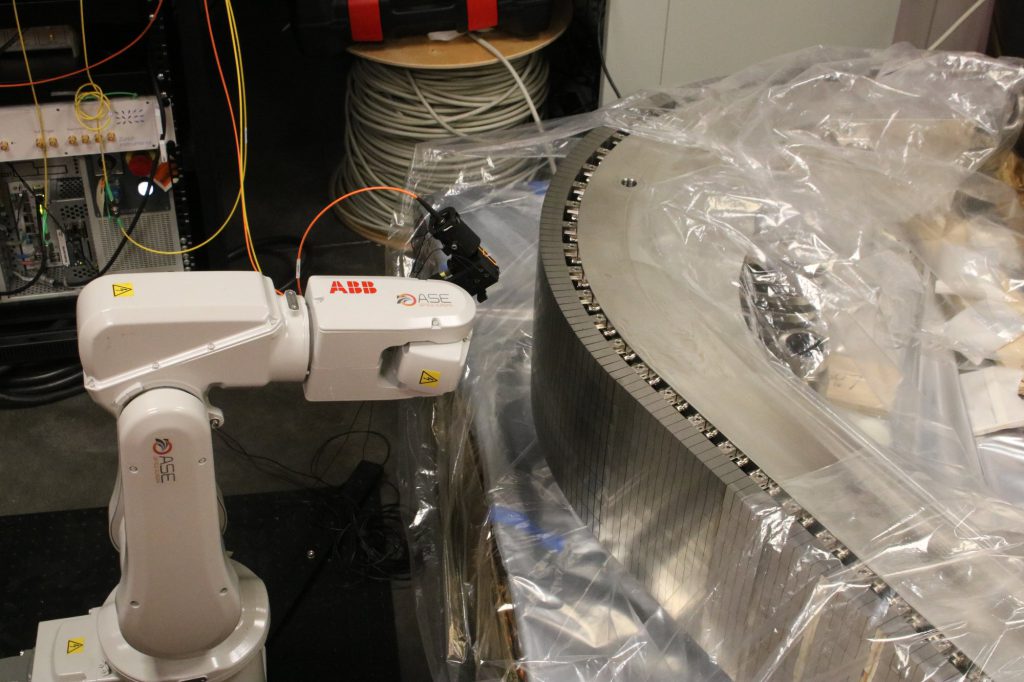

For nearly two weeks, a team of experts used the IVVS probe prototype to assess its performance on the IVT. By examining 2D images and 3D point clouds, they had evidence that the system was able to operate successfully. F4E seized the opportunity of the IVT in place and decided to check another of the tools in progress—the Target Reflectivity Measurement System (Tarms), developed by ASE Optics Europe. To produce images of the core of the ITER device, the viewing system will rely on laser beams, almost like torches in a cave with no light. However, when light falls on components the reflection coming back varies depending on the distance, the position/angle and surface. For instance, if a surface is very shiny like a mirror, it tends to reflect the light without scattering it and as a consequence, not much light bounces back to the scanning system. Conversely, if the surface of the component is less shiny, or its angle is such that allows the reflection of light to spread to the IVVS, we get to see more inside the machine. The system developed by ASE Optics Europe calculates the reflectivity of the light on the surface, and with the help of a mathematical model, engineers can forecast the performance of the IVVS on any other component inside the vessel of the ITER device.

Testing two systems on one prototype was not only effective, but also a clever move to capitalise on expertise and resources in one go. “Looking at the data that we were able to collect thanks to the tests performed, this is a success story because we start to get real images and metrology from inspections on ITER-like components. Moreover, this exercise highlights how collaboration pays off in practice between teams inside and outside F4E. We had the opportunity to try our IVVS equipment on an ITER prototype in the facility of one of our contractors. The input will feed into the final specifications and get us closer to the real system deployed in ITER,” explained Carlo Damiani, F4E Programme Manager for Remote Handling.