How to transmit signals inside the ITER Vacuum Vessel?

The divertor cassettes will be placed at the bottom of the vacuum vessel to extract heat and ash produced by the fusion reaction.

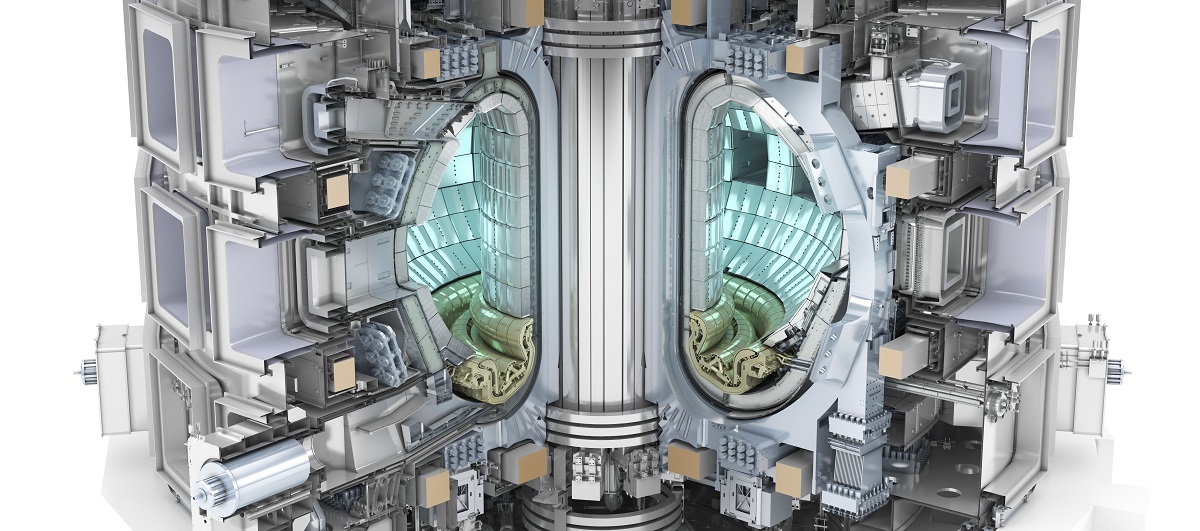

At the bottom of the ITER Vacuum Vessel, there will be an area that the impurities resulting from the fusion reaction will fall. The divertor, as it is called, will form a massive “ashtray” made of 54 cassettes able to withstand extremely hot temperatures and high neutron fluxes. Amongst them, 16 cassettes will host some sensors to collect relevant data for the ITER experiment.

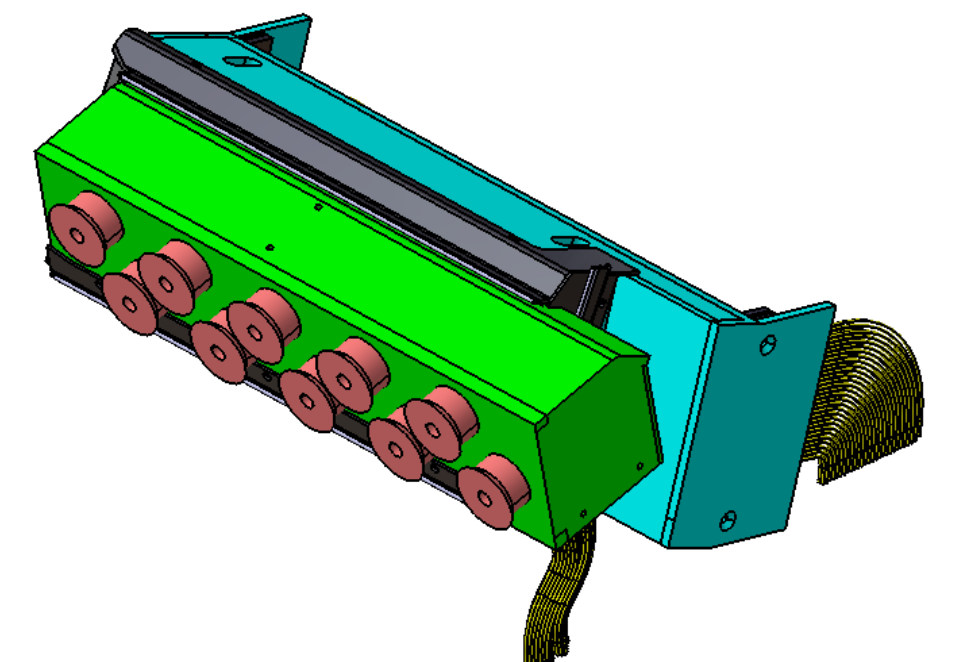

Apart from collecting the information, transmitting it outside the vacuum vessel will be equally important. F4E has signed a contract with Gutmar to design and manufacture an electrical system to perform this task. The In-Divertor Electrical Services (IDES), as known to engineers, will connect sensors mounted on the divertor cassettes to electrical cabling in the vacuum vessel, which will transmit the signals outside the ITER device for experts to analyse them.

This is a challenge in itself, but that’s not the end of it. Remote handling will be used to extract and replace the cassettes several times during ITER’s lifetime. As a result, the IDES connectors must be operated with a remote handling arm. “We are in front of a very challenging design. This connector is located on a very harsh and hot area, where it receives a high neutron flux. Besides, the area is congested with other equipment, so the remote handling arm used to connect or disconnect the equipment will need to perform a very precise sequence of movements to achieve its goal. A large number of simulations and mock-ups are being prepared to make sure we succeed with this challenge,” explains Miguel Pérez, F4E Project Manager in charge of this contract.

In total, 16 electrical connectors will be needed to handle 3 000 cables distributed throughout the walls of the vacuum vessel with the help of hundreds of mechanical supports. Engineers from subcontractor IDOM are building on the preliminary design by VTT to develop a final design of IDES, and Gutmar will then manufacture the system to deliver it in 2025. The contract, with a budget of 17 M EUR, includes another part aimed at manufacturing around 10 000 mechanical supports to hold cabling installed in the vacuum vessel and junction boxes to connect cables together. This part of the contract is expected to be completed early in 2023.