How will we measure changes in the ITER magnetic field?

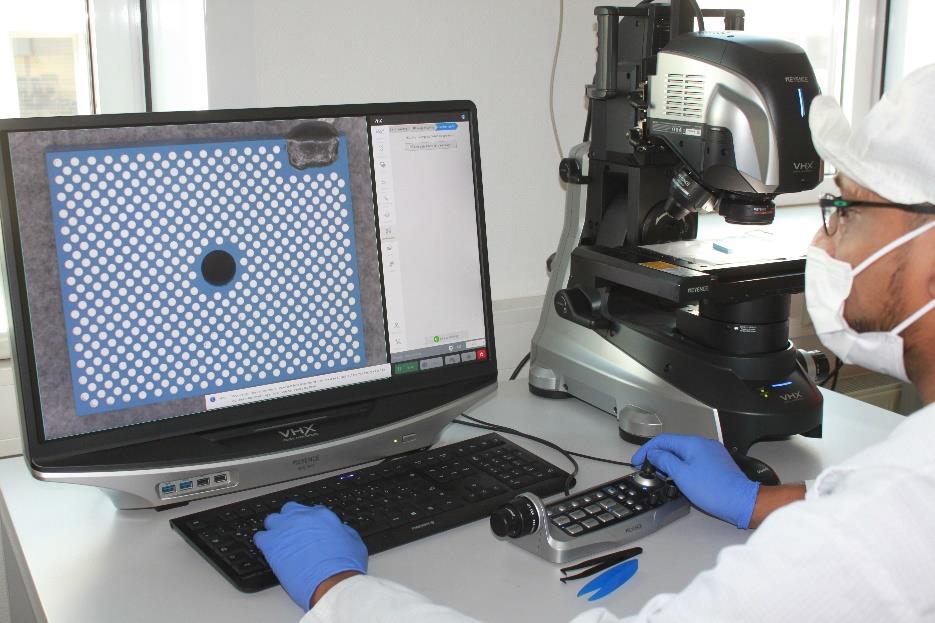

A technician is inspecting the sensor coil in VIA electronic, Germany.

Inside the ITER Vacuum Vessel, there will be many diagnostic systems that will act as the eyes and ears of the engineers. These systems will keep scientists informed on the composition, temperature and other characteristics of the plasma. The so-called LTCC sensor coils will be in charge of measuring the changes in the magnetic field, a relevant parameter to control the conditions of the experiment.

The last batch of these sensors has just been manufactured by F4E’s contractor VIA electronic. After the delivery of the first batch in July 2020, and the second in December 2020, the third and final batch, containing 140 sensors, was sent in April 2021 to Sgenia. There, engineers are assembling the sensors into the platforms that support and cover them. Once assembled, they will deliver them to Elytt Energy for calibration and finally to ITER Organization.

The series production of the sensors started in January 2020. In a nutshell, engineers take sheets of a ceramic polymer material on which they print thin silver paste tracks. They stack all the sheets to form a 36-layer object. Then, they bake the set at around 850 °C to make it compact and, last but not least, they weld the connection wires to complete the Low Temperature Cofired Ceramic (LTCC) coil.

“It was challenging to deliver a high number of sensors pushing the manufacturing technology to the limits in terms of complexity and tight tolerances. But in the end VIA electronic rose to the challenge and delivered a good product that we will be using for many years of ITER operation,” concludes Ulrich Walach, F4E Technical Responsible Officer for this project.