F4E delivers thousands of in-vessel supports to wire up ITER

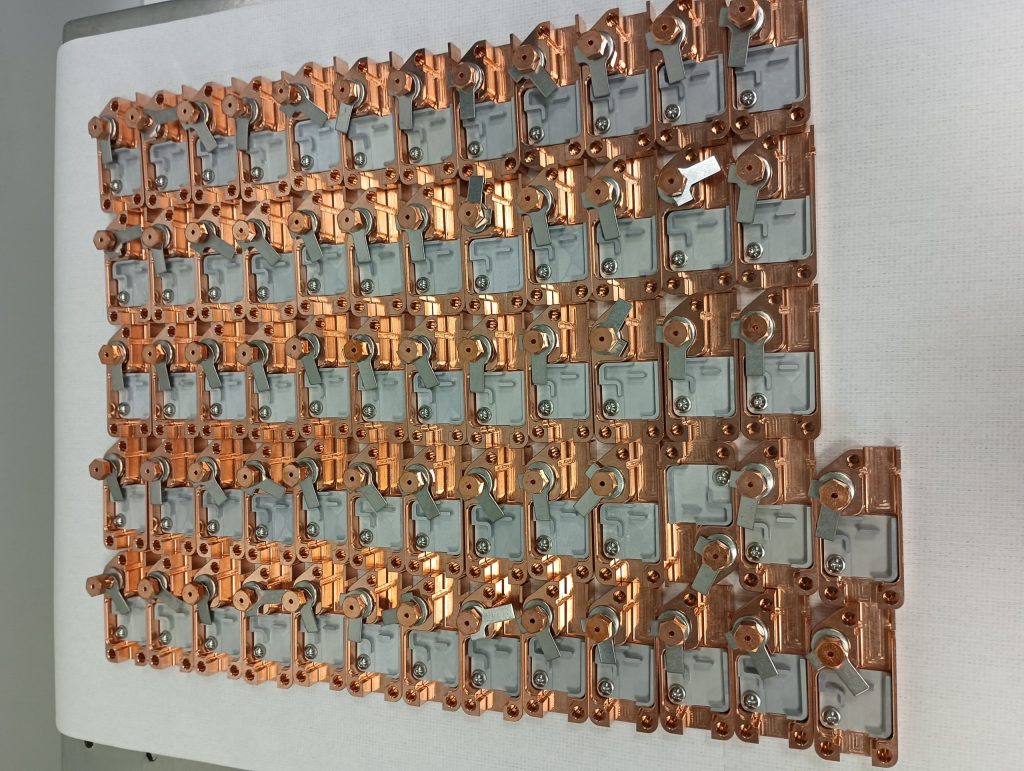

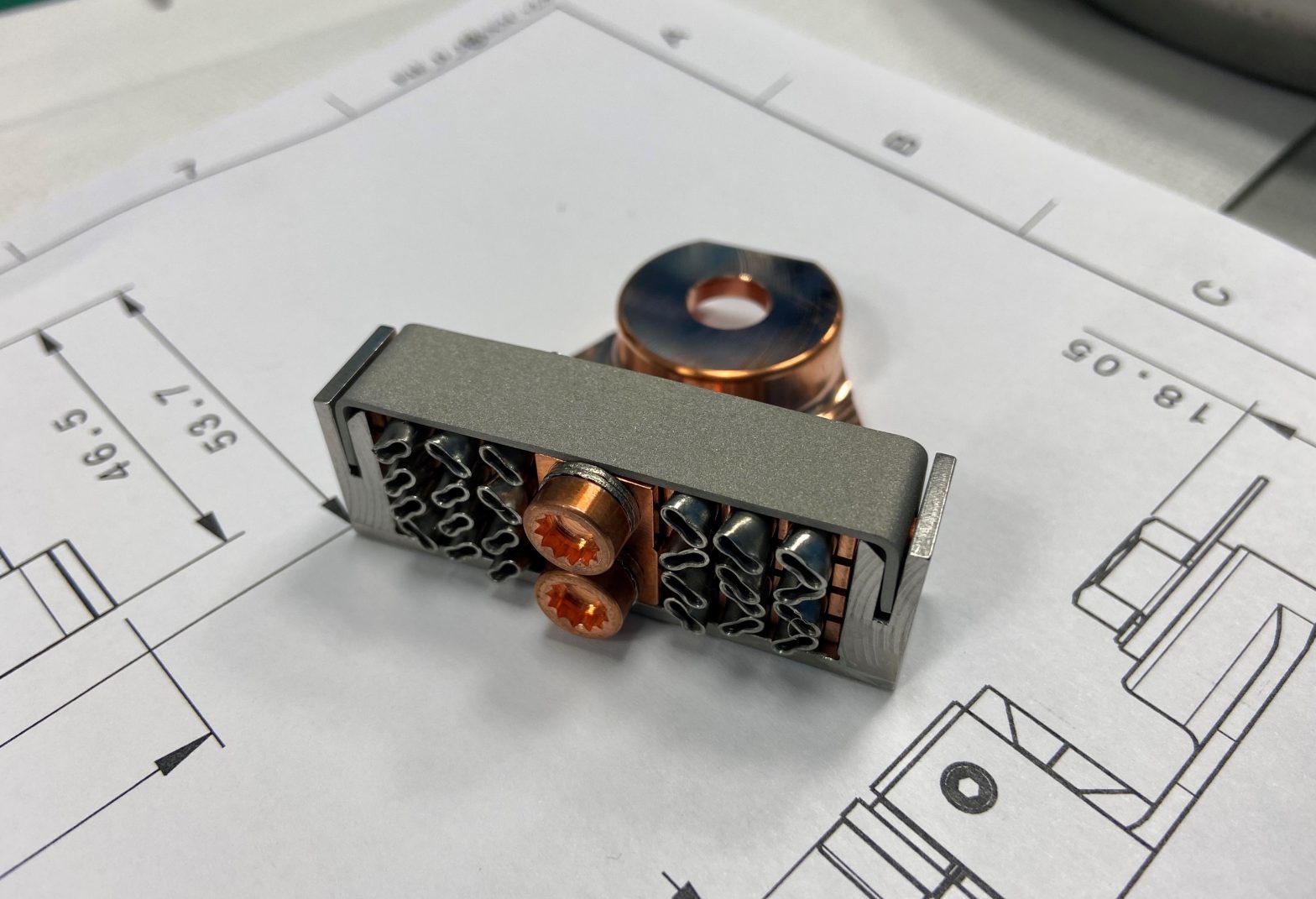

A mechanical clamp, part of the In-Vessel Supports for ITER diagnostic cables, during a visual inspection. ©F4E

ITER’s Vacuum Vessel, the massive steel container housing the fusion reaction, will be equipped with an array of technologies to monitor the experiment. Like eyes inside the machine, dozens of diagnostic sensors will help scientists to track parameters such as the plasma’s behaviour or changes in the magnetic field. Their electrical signals will travel from inside the chamber, through the vacuum vessel and towards the building where they will be translated into data. This journey will take place via an advanced cabling network, akin to ITER’s nerves.

The diagnostic cables are under production by Thermocoax for Fusion for Energy (F4E), with most of the batches already delivered. They feature a mineral insulation and a stainless-steel jacket to endure the harsh environment inside ITER. They also have special terminations at both ends to keep the ultra-high vacuum level.

In total, the cables will form an 18-km-long web branching beneath the ITER blanket, all around the machine. To secure them onto the vessel’s surface, assemblers will use thousands of small custom-made supports manufactured by Europe.

In 2021, F4E signed a contract with Gutmar, a Spanish SME specialising in precision machining. Three years later, the series production is completed and the last of the many batches has been delivered. In fact, the number of pieces was so vast that colleagues at ITER had to team up to inspect and count them before signing off the shipment. The total tally: 11,700 clamps to hold cable looms, 57,000 clips for single cables and 500 junction boxes for electrical connections.

“The in-vessel supports are essential to attach securely the rigid cables along their precise routes. They also help distribute the heat loads more evenly across the cables. We worked closely with the supplier to ensure that the equipment meets ITER’s strict quality standards,” explains Ángela Hernández Sanchez, Project Manager at F4E.

“Throughout the production, we had to navigate through design adjustments and adapt our processes. By keeping a flexible and collaborative mindset, we managed to deliver the numerous pieces on time and to specification,” celebrates Alba Fibla, Project Manager at Gutmar.