Europe delivers all cold valve boxes for the ITER neutral beam cryopumps

Technicians unload one of the cold valve boxes at a warehouse in ITER. ©F4E

Fusion for Energy (F4E) and its supply chain have delivered on yet another contract for ITER. The arrival onsite of the three cold valve boxes for neutral beam heating marked the last major milestone of a Procurement Arrangement signed in 2017. As part of it, F4E has worked with several companies to design and manufacture equipment to dispatch cryogenic fluids around the machine.

The main clients of the refrigeration network are the cryopumps. These powerful ‘vacuum cleaners’ will use ultra-cool charcoal panels to trap gas particles. Eight of them will serve ITER’s vacuum vessel and cryostat, whilst three others will work for the neutral beam injectors, ensuring the heating beams travel in immaculate conditions. Each pump will be paired with a cold valve box (CVB), that will supply them with precise doses of helium across a wide temperature range, from -269 °C up to 210 °C.

F4E worked with Research Instruments (RI) to produce the CVBs (plus one warm regeneration box). The German company, in collaboration with subcontractors Cryoworld and Velan, delivered eight units for the torus and cryostat cryopumps in 2023. After that success, F4E entrusted them with three more for the neutral beam cryopumps.

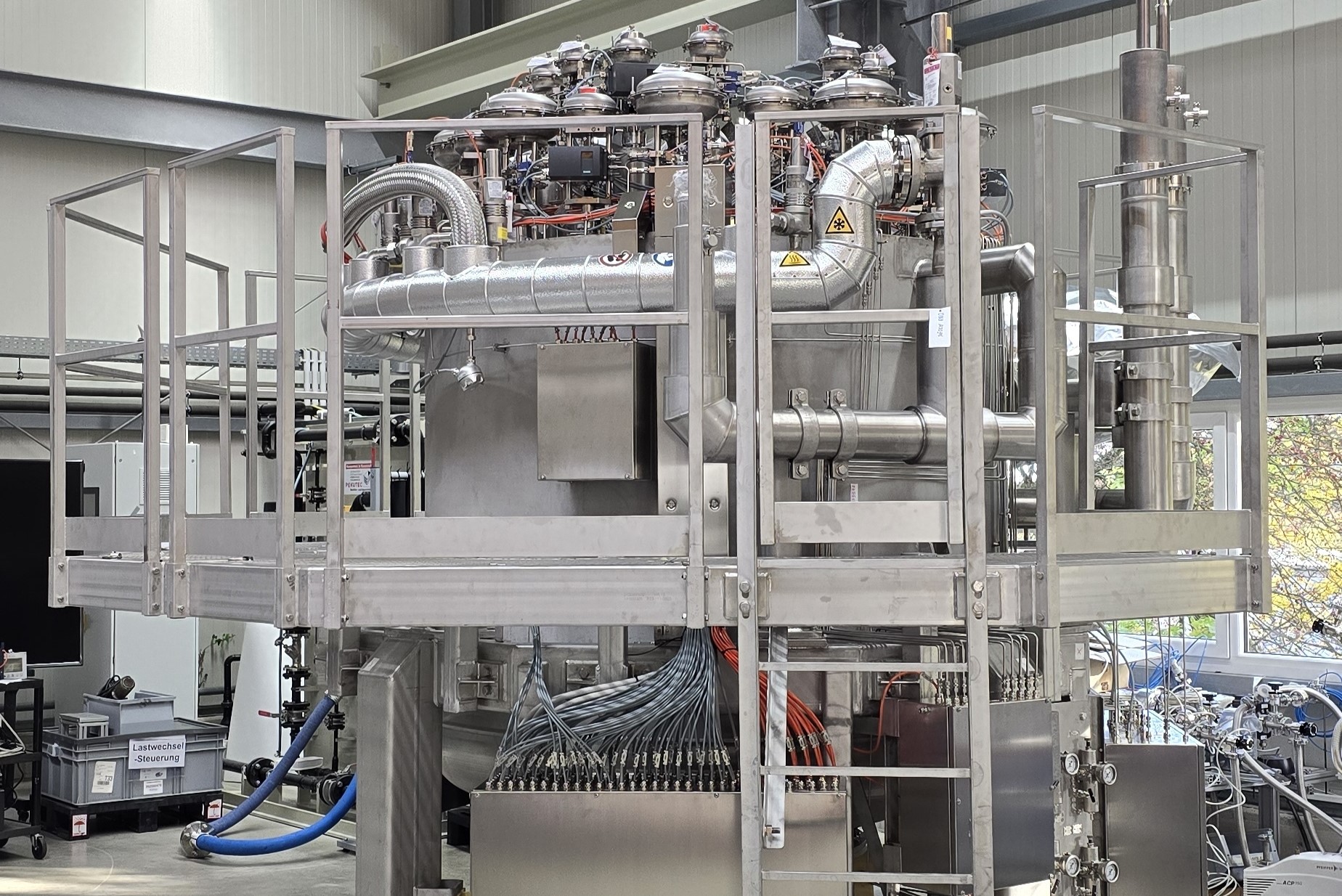

Building on the design and the experience of the previous batch, production moved swiftly for the new CVBs. Their assembly is an intricate jigsaw of pipes, sensors and dozens of special valves inside a container of 3 m in height and around 2 m in diameter. The components went through several tests, checking for leaks, pressure or valve functionality. The positive result earned them a one-way ticket to Cadarache, home of the ITER project in France.

“We are happy to have finished manufacturing and testing of the cold valve boxes, which are even larger and more complex than the eight we delivered two years ago. We thank our partner Cryoworld for their excellent support and F4E for their valuable collaboration. Such success is only possible when all parties are committed to the highest quality and trustful cooperation,” says Michael Pekeler, Managing Director at RI. “This delivery is the culmination of a collaborative journey between F4E, ITER Organization and the supplier. RI has proven to be an engaged and reliable partner, proactive in solving engineering challenges,” celebrates Lluís Mora, F4E Project Manager.

Earlier this month, F4E completed the delivery of the cryodistribution control system. The electronics were manufactured by Framatome, while GTD developed the software and designed the first-of-a-kind cabinets. Together, they will allow to orchestrate the entire cold circuit. Experts will use the system to operate the valves inside the CVBs and regulate the flow of cryogenic fluids. They will also monitor parameters such as temperature, pressure, and flow rate.

With only auxiliary equipment left, F4E’s Fuel Cycle team is very close to wrapping up this ITER Procurement Arrangement. “We’re very proud to meet the ambitious schedule set eight years ago. In doing so, we have strengthened Europe’s industrial capability in complex vacuum and cryogenic components,” concludes Josep Benet, F4E Programme Manager. In parallel, F4E’s team is working to launch the tender for the production of the neutral beam cryopumps, after the recent installation and commissioning of the prototype in MITICA.