Engineers design equipment to measure the temperature of the plasma-facing components

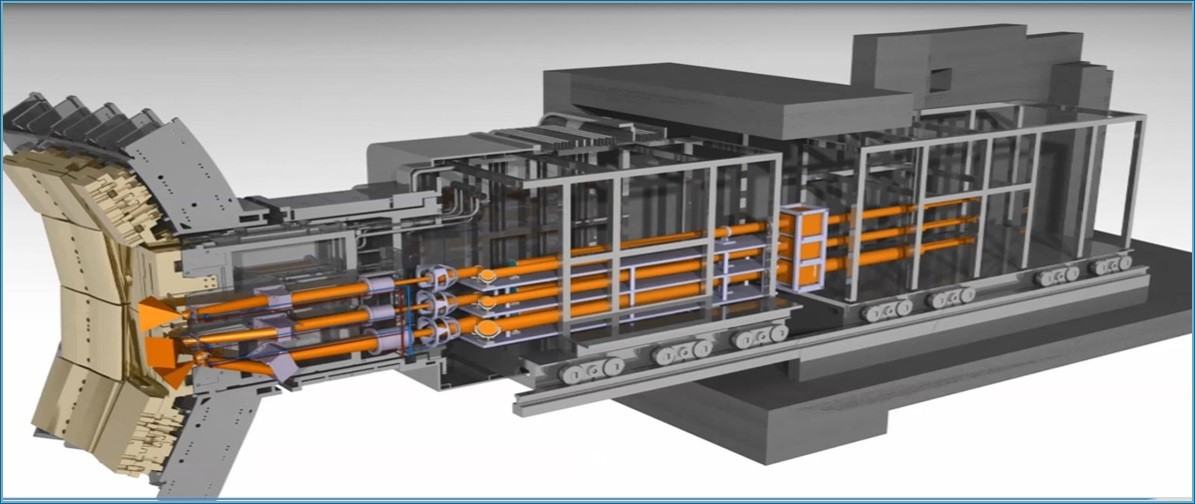

Integration of the Wide Angle Viewing System in the Equatorial Port 12.

The components facing the super-hot plasma will be exposed to a harsh environment. The ITER Equatorial Port Wide Angle Viewing System (WAVS) is an optical diagnostic that will provide real-time measurements of the visible and infrared light coming from the divertor and the main chamber wall. These measurements will contribute to the safe operation of the machine by providing information about the temperature of the plasma-facing components, preventing any potential damage.

The WAVS comprises 15 views (lines of sight) distributed in four vacuum vessel ports and covers about 80% of the first wall surface –the wall facing the plasma. For each line of sight, the light emitted by the plasma-facing components is collected by an entrance pupil, and travels more than 10 m through a series of mirrors and lenses up to the cameras located at the back-end of the port-cell. In total, the WAVS will include more than 600 opto-mechanical components, plus other non-optical ancillary systems.

F4E is currently performing the final design of this system (in the so-called equatorial port 12) and Final Design Review meetings are scheduled for 2022. The on-going collaboration with CEA, CIEMAT, Bertin Technologies and INTA will also cover manufacturing follow-up (2022-2024), installation and commissioning of the system. F4E is responsible for the design of the 15 lines of sight and the procurement of the 11 lines distributed in equatorial ports 3, 9 and 12. ITER Organization is responsible for the procurement of the remaining 4 lines of sight in equatorial port 17.

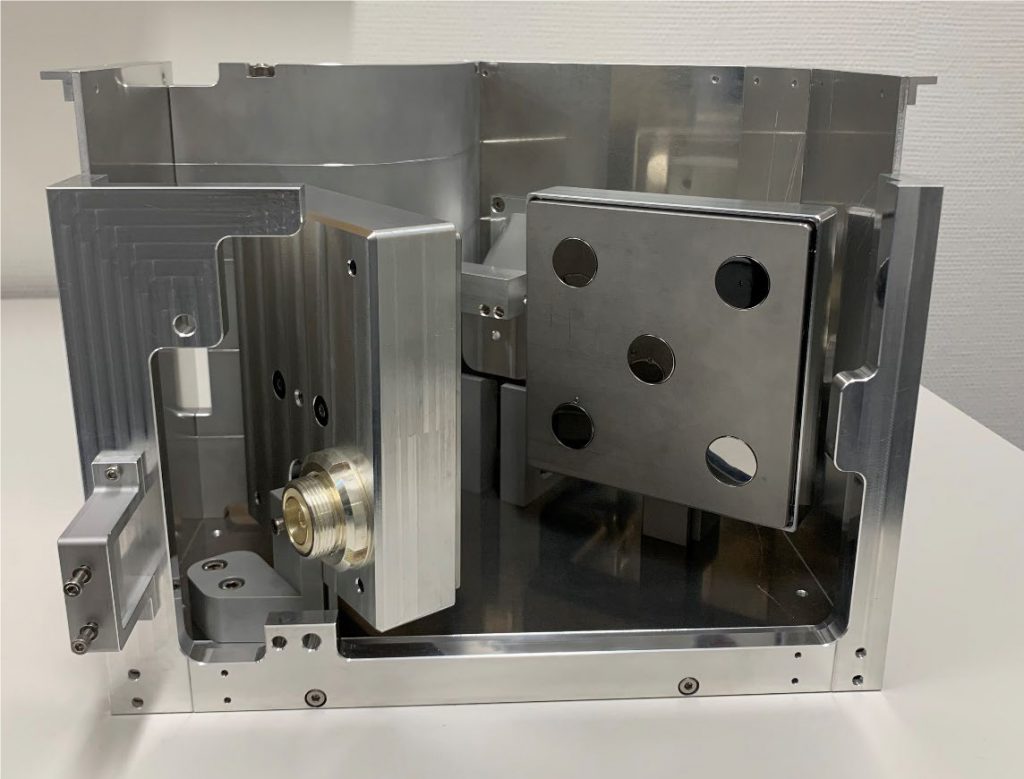

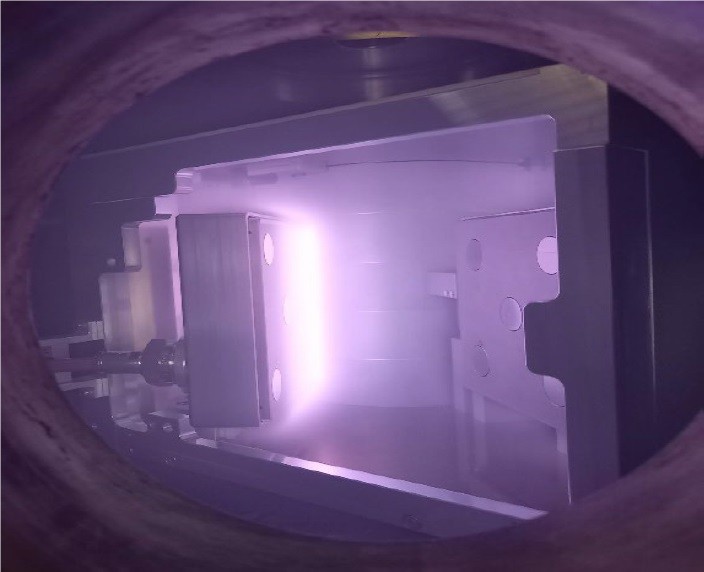

As part of the design activities, extensive R&D tasks were performed in the last years. A particular emphasis was put on an issue that is common to all optical diagnostics in ITER: the first mirror is polluted through the entrance pupil by the plasma. After a few tens of plasma pulses, the diagnostic may be blind due to the deposit on its surface. “It is therefore necessary to periodically clean the mirror in-situ. A radio-frequency technique has been successfully developed in collaboration with the University of Basel. Final tests are currently conducted on a scale-1 prototype with the final WAVS First Mirror Unit geometry,” explains Frederic Le Guern, F4E Project Manager for this system.

Furthermore, due to the very harsh conditions of ITER, comprehensive tests (irradiation, baking, steam ingress…) aiming at selecting suitable materials for the optical components have been performed with partners (CIEMAT, SCK-CEN and KIT) in the last years. They have provided WAVS design engineers with robust solutions to complete the design stage and thus advance to manufacturing with full confidence. The Equatorial Port 12 WAVS, which is the first one to be fabricated, is expected to be delivered to ITER Organization during 2024.